Diamond Dotted Paper in Transformers: Key Benefits & Applications

Introduction

Diamond Dotted Paper (DDP) is a key insulating material widely used in oil-immersed power transformers. Known for its excellent electrical insulation properties and mechanical strength, DDP plays a critical role in maintaining the safe and stable operation of high-voltage equipment. In this article, we’ll explore how DDP works in transformers, its technical specifications, and the reasons it remains a preferred insulation solution for manufacturers worldwide.

What Is Diamond Dotted Paper?

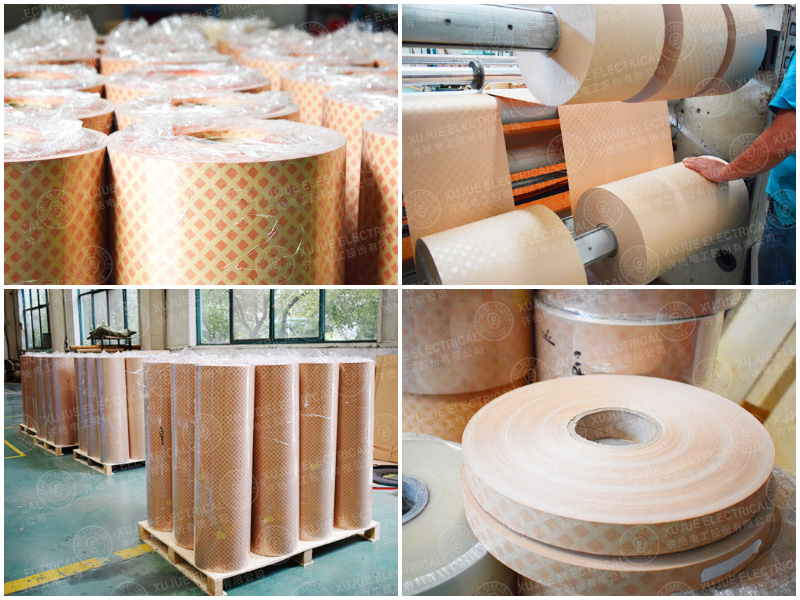

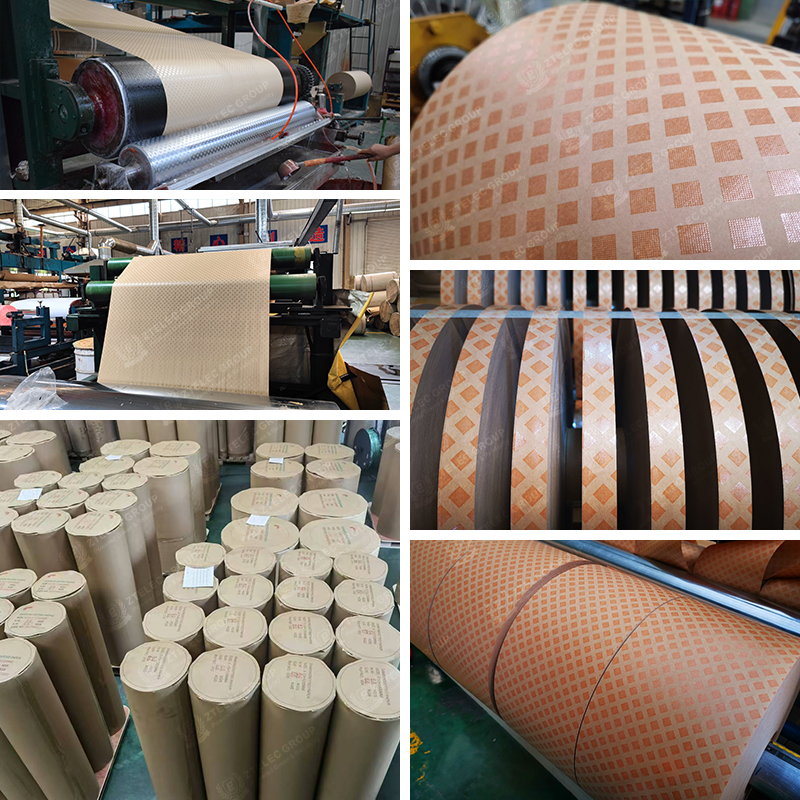

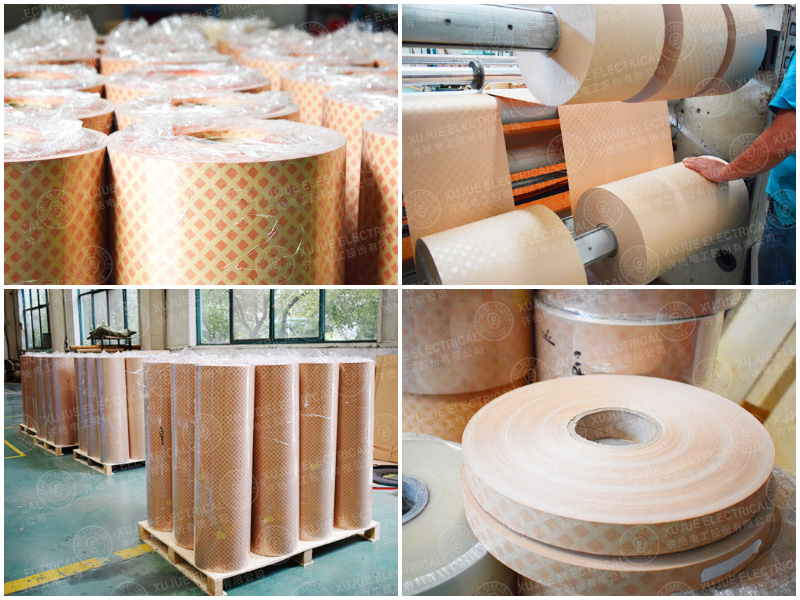

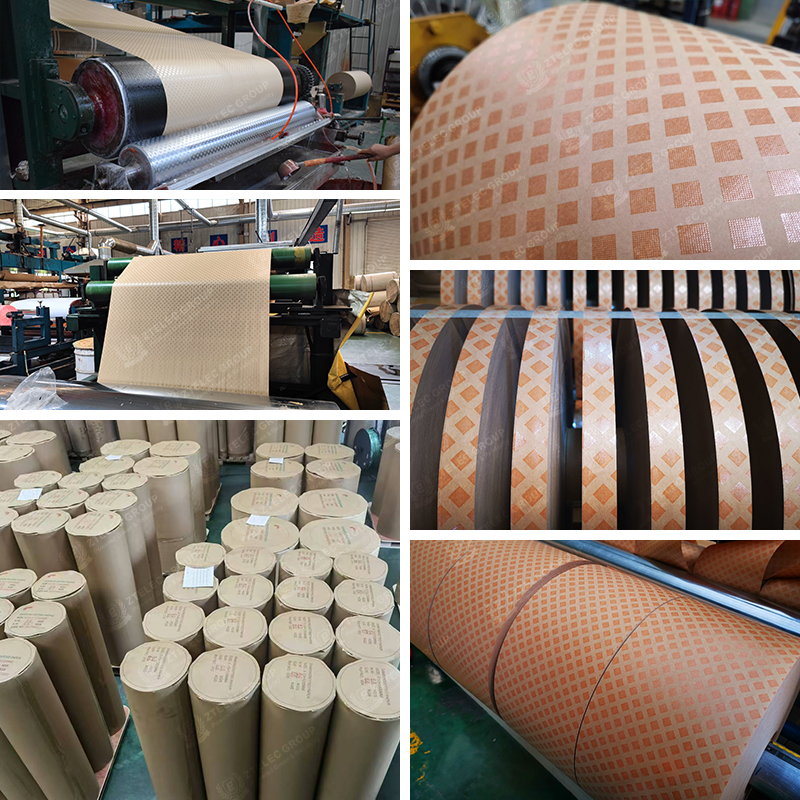

Diamond Dotted Paper is a type of electrical insulation paper coated with epoxy resin in a diamond-shaped pattern. The base paper is typically high-purity electrical grade cellulose, while the resin is a thermosetting epoxy that activates under heat and pressure. When transformer coils are wrapped with DDP and baked, the epoxy resin melts and bonds the windings together, providing strong adhesion and insulation.

Key Technical Parameters

Base Material: Electrical-grade insulating paper (usually 100% pure cellulose)

Resin Type: Epoxy thermosetting resin

Coating Pattern: Diamond-shaped dots, typically spaced 15–20 mm apart

Thickness Range: 0.05 mm to 0.25 mm (depending on application)

Thermal Class: Typically Class A (105°C), with modified types available for higher classes

Dielectric Strength: ≥ 8 kV/mm (dry), with oil impregnation increasing performance

Bonding Strength: Excellent after heat curing (typically at 90–120°C)

Compatibility: Fully compatible with transformer insulating oils

Applications in Power Transformers

In power transformers, DDP is primarily used for:

Layer Insulation: Wrapping between copper or aluminum windings to provide electrical isolation and mechanical bonding.

Spacer and Channel Creation: Assisting in oil circulation and heat dissipation within the transformer structure.

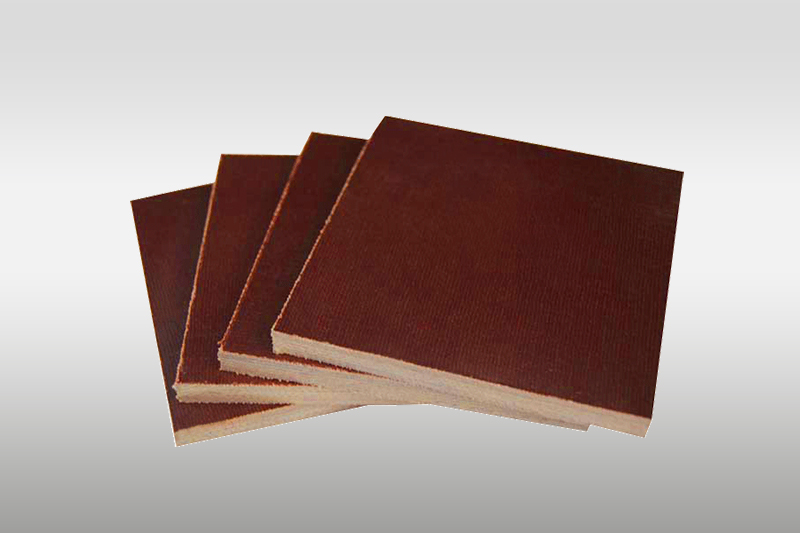

Structural Reinforcement: After heat curing, the resin creates a rigid structure that resists vibration and movement during operation or transport.

These applications are critical in both distribution and large-scale power transformers, particularly in environments where mechanical stress and temperature fluctuations are common.

Advantages of Using DDP

Enhanced Dielectric Performance: The combination of paper and epoxy ensures high insulation resistance and low dielectric loss.

Improved Mechanical Strength: Cured epoxy bonds the layers tightly, preventing displacement and reducing the risk of partial discharge.

Thermal Endurance: Maintains dimensional stability under high temperatures and prolonged operation.

Oil Compatibility: Performs reliably in oil-immersed conditions, allowing for long-term use without degradation.

Production Efficiency: Easy to wrap and process, DDP reduces production time and increases transformer reliability.

Why Manufacturers Choose DDP

Transformer manufacturers favor DDP because it combines cost-efficiency, reliability, and long-term performance. Its ability to bond windings, resist aging, and perform well in thermal and electrical environments makes it an ideal insulation solution for modern transformer design.

Conclusion

Diamond Dotted Paper is an indispensable material in the transformer insulation system. With its proven track record in improving electrical insulation, structural integrity, and thermal performance, DDP continues to be a trusted choice for transformer OEMs and engineers globally. As demand for energy infrastructure grows, the role of high-performance insulation materials like DDP becomes more critical than ever.