A Practical Guide to Electrical Paper Pressboard in Transformers

Transformers are critical components in modern power grids, transferring energy safely and reliably between voltage levels. However, behind their flawless operation lies a range of insulating materials that keep them stable and safe. Among these, electrical paper pressboard — commonly known as transformer pressboard or electrical insulating paperboard — plays a vital role in ensuring both electrical and mechanical performance.

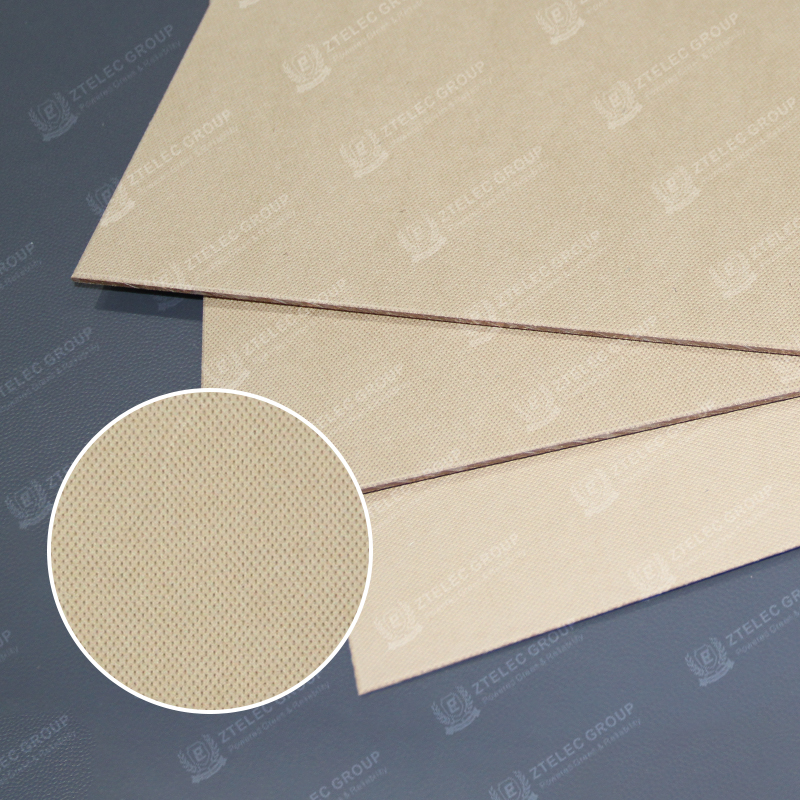

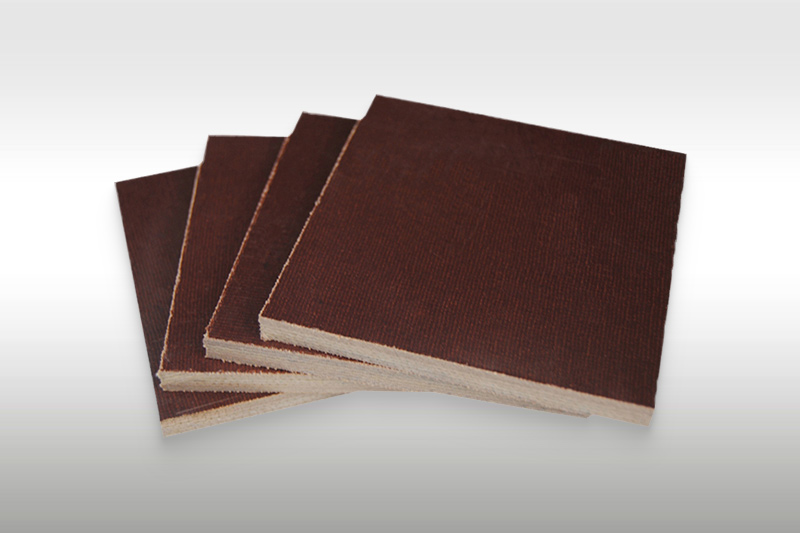

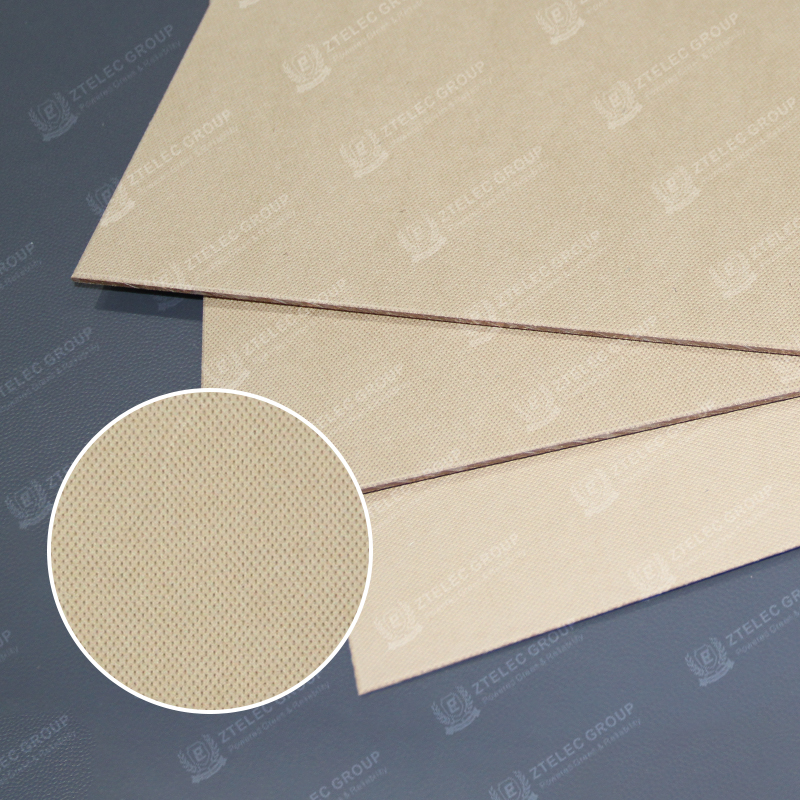

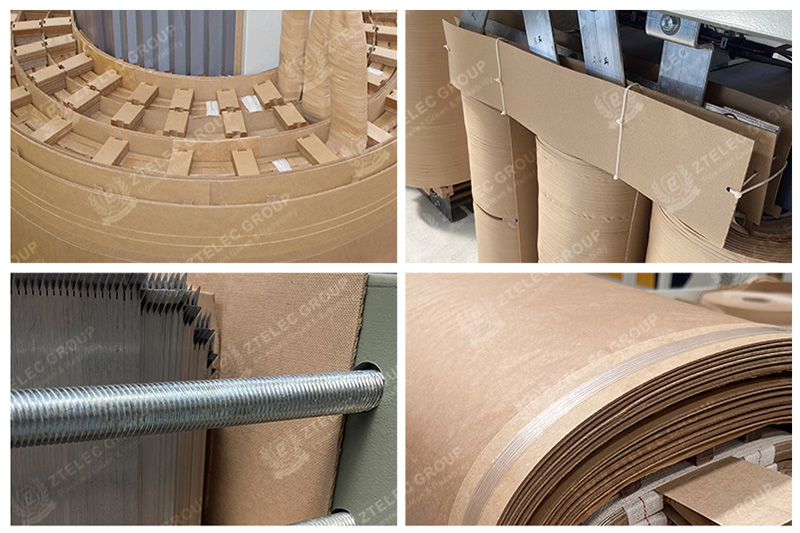

Paper pressboard is made of 100% high purity sulphate wood pulp by hot pressing. It is pressed into dense sheets with high dimensional stability and moisture resistance, making it an ideal insulating medium inside oil-immersed transformers.

Key Applications in Transformers

Electrical Paper Pressboard serves several crucial functions in a transformer:

1. Layer Insulation

Used to separate conductive windings, preventing dangerous short circuits and ensuring safe voltage distribution.

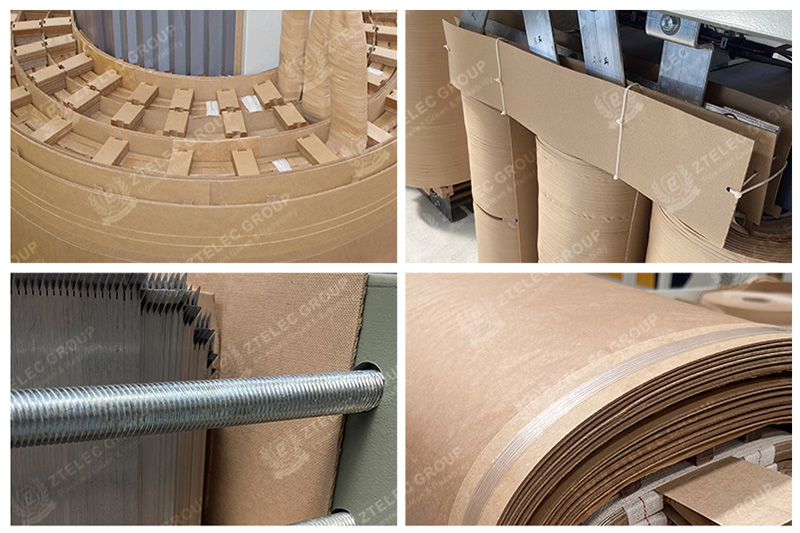

2. Structural Support

Forms rigid components such as cylinders, spacers, barriers, and press rings, giving physical stability to transformer windings under mechanical stresses.

3. Oil Ducts and Spacers

Designed to maintain proper oil circulation channels inside the transformer, which is critical for effective heat dissipation and cooling.

4. Core Insulation

Provides protective barriers between the transformer core and windings, avoiding eddy currents and ensuring high operational efficiency.

Advantages of Using Electrical Paper Pressboard

Electrical paper pressboard stands out for its excellent performance in demanding transformer environments. Some of its top benefits include:

► High Dielectric Strength: Can resist high voltages without electrical breakdown.

► Good Mechanical Strength: Withstands compression and bending forces from electromagnetic loads.

► Thermal Stability: Remains dimensionally stable even in elevated operating temperatures.

► Oil Compatibility: Works seamlessly with transformer oil, avoiding contamination or chemical reactions.

► Environmentally Friendly: Based on renewable cellulose, with low environmental impact.

These properties make it a trusted choice for power transformers, distribution transformers, and reactor units worldwide.

Installation and Handling Tips

Proper handling of electrical paper pressboard is essential to maintain its properties:

► Store in a dry, clean warehouse with stable humidity to avoid moisture pickup.

► Handle with gloves to prevent contamination or surface damage.

► Machine with sharp tools to minimize fiber tears and dust generation.

► Pre-dry the cardboard before installation to ensure low moisture content, improving insulation reliability.

Future Trends

With growing demand for greener, longer-lasting transformer solutions, modern electrical paper pressboard is evolving with enhanced resin impregnation, improved surface finishes, and optimized mechanical strength. This ensures that transformers can continue to perform safely and efficiently for decades.

In summary, electrical paper pressboard is a core material for transformer insulation systems, combining safety, durability, and eco-friendliness. If you’re seeking a reliable solution to protect and optimize your transformers, consider premium-grade insulating pressboard as a key investment.