Product Description

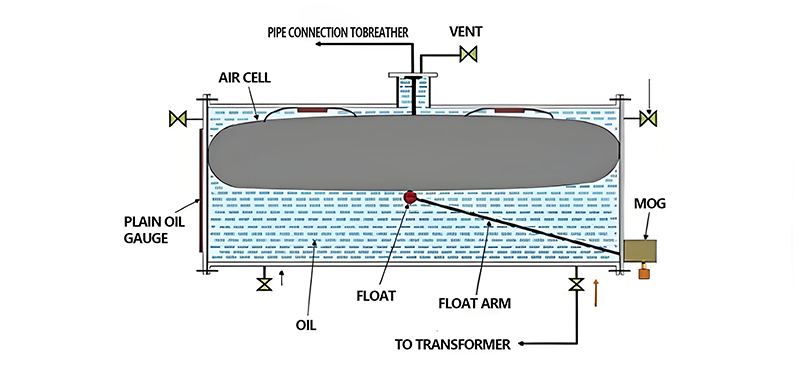

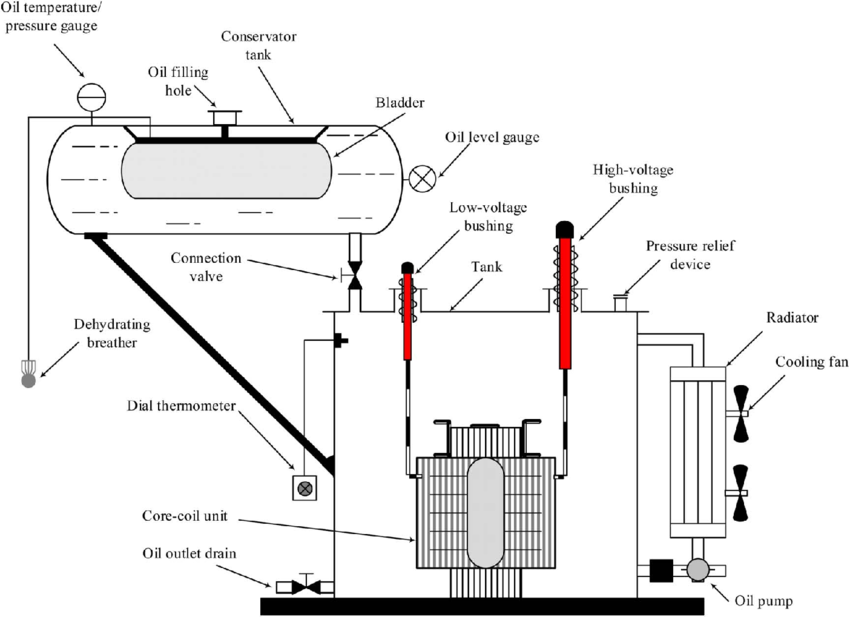

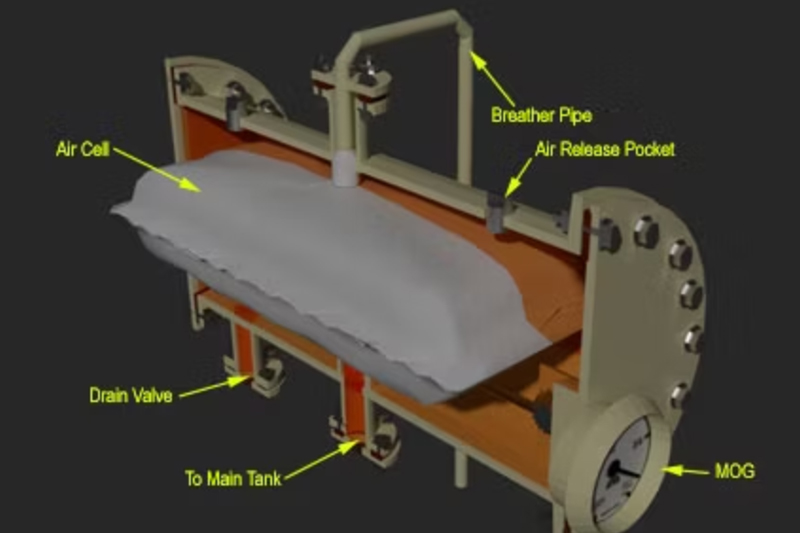

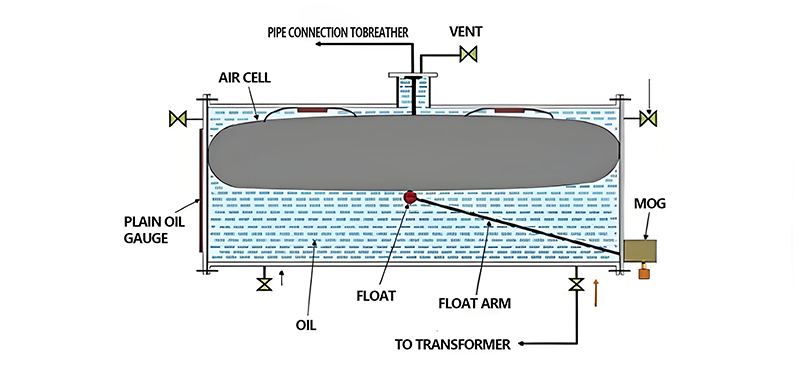

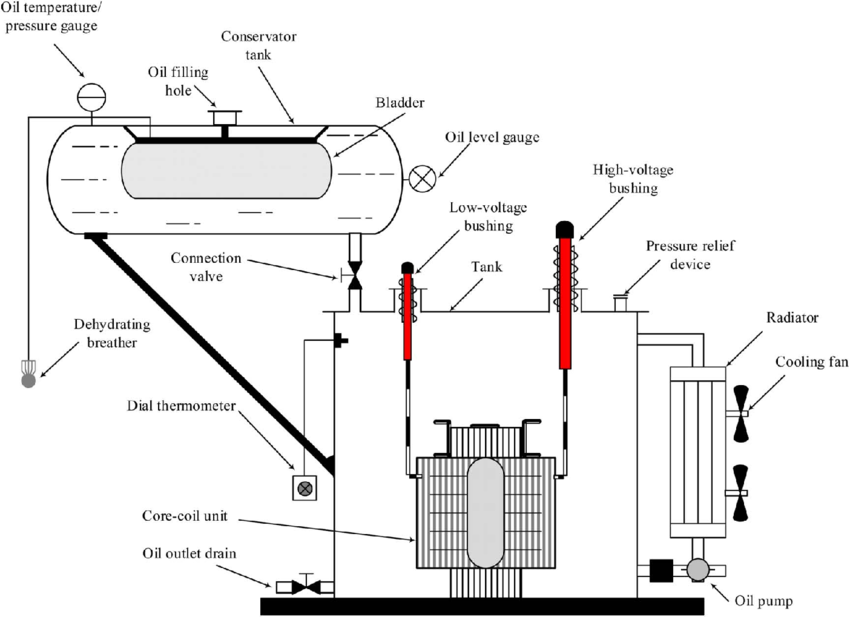

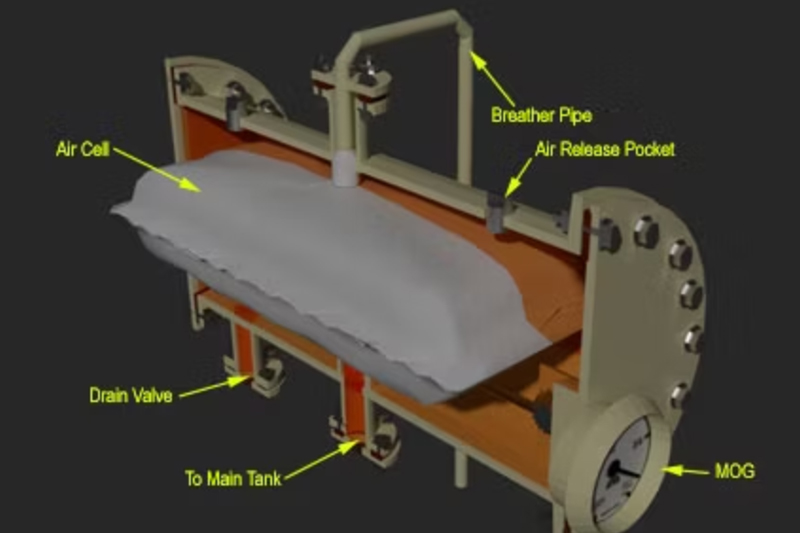

ZTelec Yuguang Diaphragm (Diaphragm Conservator) is fitted inside a conservator tank, isolating insulating oil from the atmosphere, and thus preventing contamination of gas and/or moisture from coming into contact with the transformer oil due to oxidation and hydrolysis. The bag is vented on the transformer through flange type mounting such that it inflates or deflates to accommodate oil volume displacements due to changes in the transformer temperature.

ZTelec Yuguang Diaphragm are manufactured using time tested Nitrile Rubber Coated Nylon Fabric and a thick coating of Elastomers i.e. Acrylonitrile Butadiene Rubber (NBR), Polychloroprene (CR) and Hypalon (CSM). The rubber compounds are so formulated, so as to minimize separator degradation and resist leakage of air through membranes thus reducing the amount of air in the transformer oil. Over a period of time this air/gases can reduce dielectric strength and thereby accelerate the aging of the insulation system.

Diaphragm Parameters

Cell Material: Nitrile Rubber/Coated Nylon Fabric

Air Valve material: NBR/brass/customized rubber

Cell Color: Black/Green/Blue/customized

Level Gauge Fitting: NBR/brass/customized rubber

Finishes: NBR/Smooth surface/Clean-free-surface

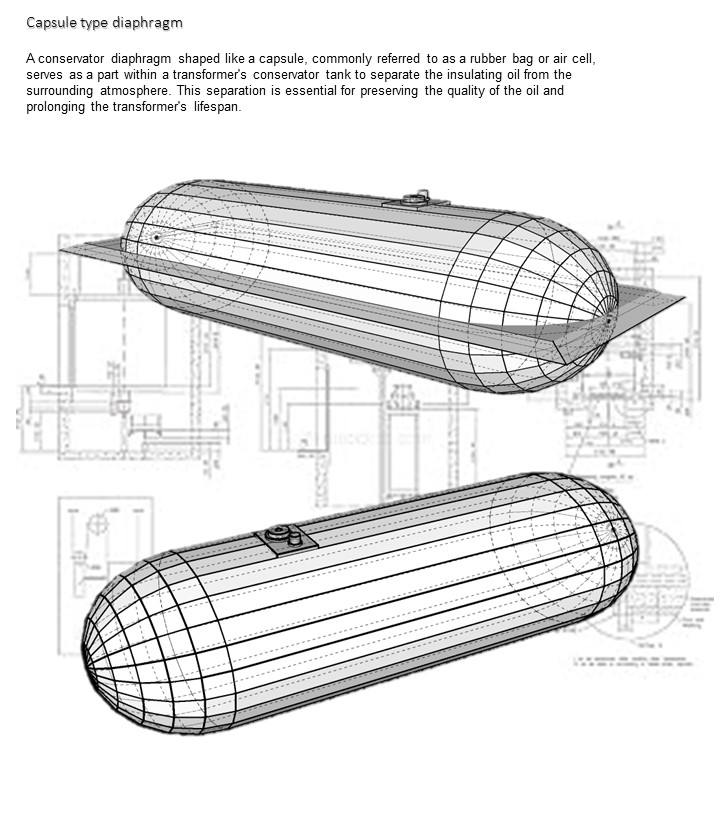

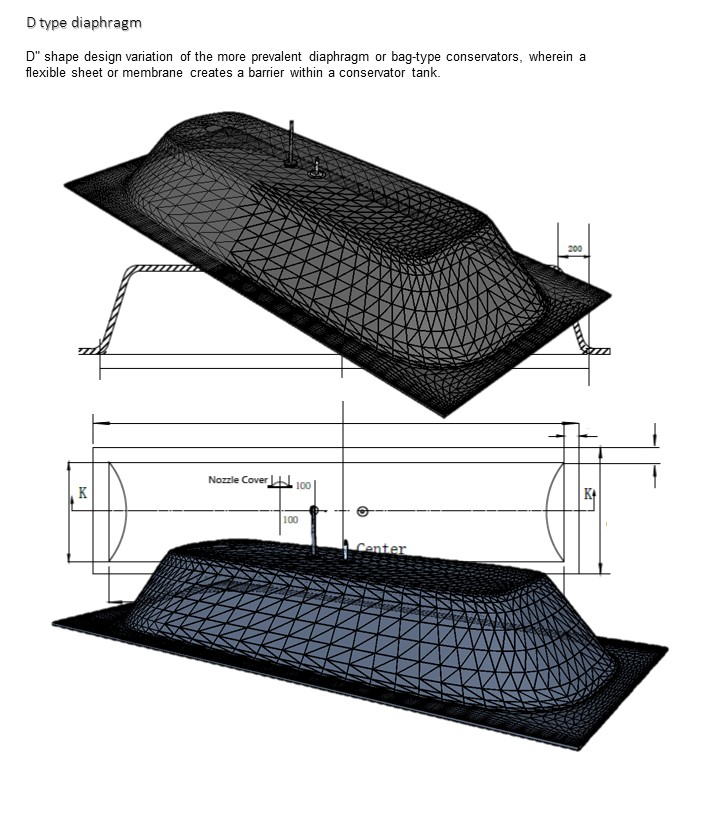

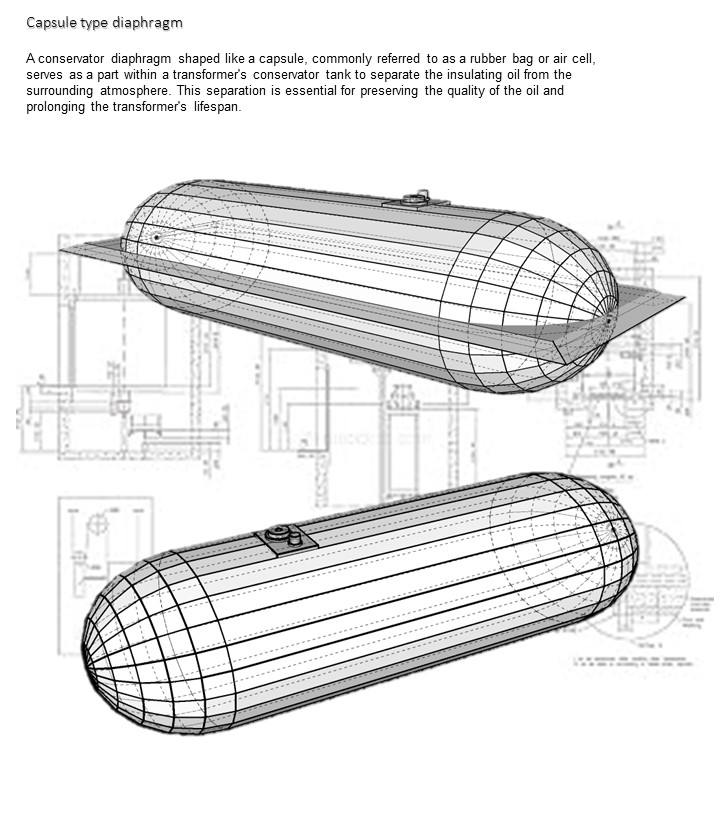

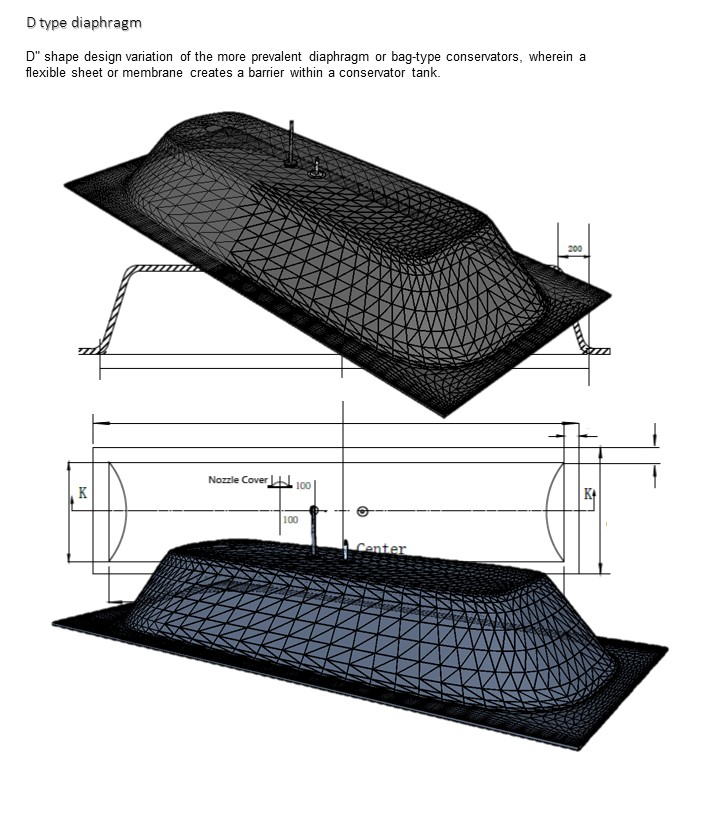

Shape: D type, capsule type, bag type or customized

Sizes and Dimensions: as per customer requirement

Material properties

Characteristics to define behavior under various conditions and influences as per applicable standard test procedures and guidance.

Reference standard: GB/T 5453-1997, GB/T1038.1-2022

Material thickness (mm): 0.7 – 1.0

Breathability: 24.5kPa x 3min

Gas tightness:

|

Tightness (time/pressure)

|

Static pressure (psi/ kPa)

|

Component

|

|

20 min

|

(0.145) 1.0

|

no detectable leakage

|

Hardness Scale: Shore A 60-65

Permeability (air as medium): 0.1Lit. (100 cubic cent) per 24hr. standard

Material elongation: 15-20%

High temp resistance: up to 100℃

Low temp resistance and endurance: up to -40℃ tested at 2hr. rate

Vol. change at 100℃ for 24 hours: 0% rate