3240 Epoxy Sheet Applications in Energy and Electronics

In today’s fast-evolving electrical and energy industries, 3240 epoxy resin sheets have become a trusted and widely adopted solution for insulation needs. Known for their mechanical strength, electrical insulation, and heat resistance, these laminated sheets play a vital role in numerous applications—from lithium battery modules to motors, transformers, and electronic devices.

What Is 3240 Epoxy Resin Sheet?

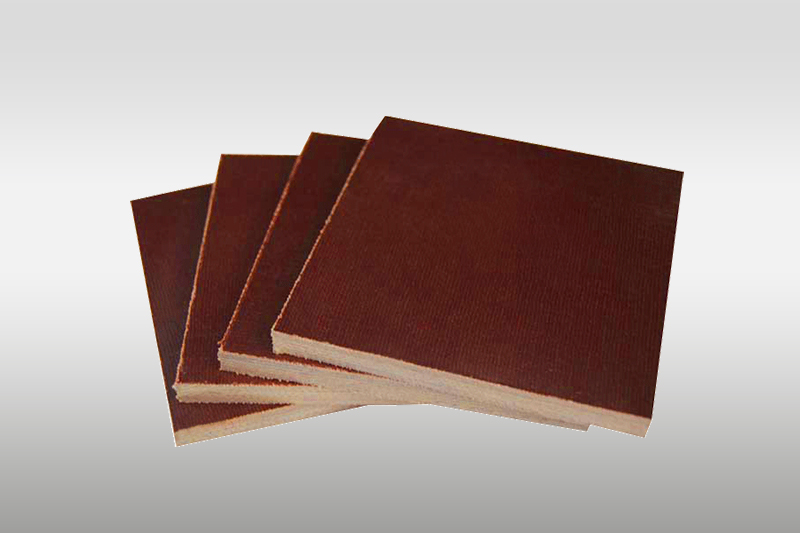

3240 is a thermoset laminated insulating material, made by impregnating glass cloth with epoxy resin, then hot pressing it into solid sheets. It complies with the GB/T 1303.1-2009 standard in China and is often equivalent to international materials like G10 or FR4, though it focuses more on mechanical and thermal performance than flame retardancy.

Key characteristics include:

1. Excellent electrical insulation at high voltages

2 .High mechanical strength and dimensional stability

3 .Good heat resistance up to 130°C (Class B)

4 .Moisture and chemical resistance

These attributes make it ideal for demanding insulation and support structures in both static and dynamic environments.

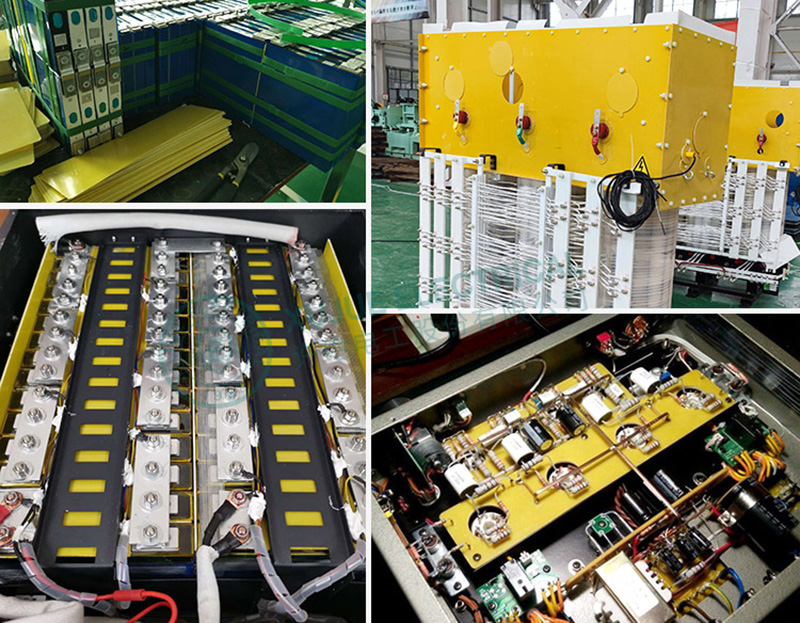

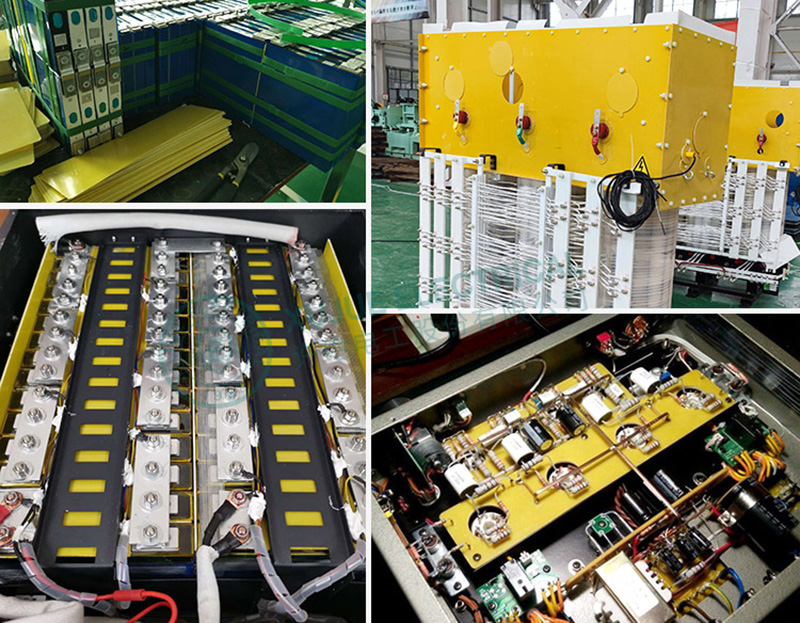

Application in Lithium Battery Pack Assembly

One of the fastest-growing use cases of 3240 epoxy sheets is in lithium battery systems, particularly for EVs (electric vehicles), energy storage units, and battery modules. Here’s how 3240 helps:

1.Cell Separation and Barrier Layers

The rigid, stable sheets are used as insulation partitions between battery cells or modules to prevent short circuits, thermal runaway, and electrical arcing.

2. Structural Reinforcement

3240 sheets provide mechanical support in battery pack casings and trays, absorbing vibration and maintaining battery module integrity under stress or collision.

3.Dielectric Shielding

Their strong dielectric properties ensure protection in high-voltage battery applications, effectively isolating live components and reducing safety risks.

4.Thermal Resistance

With Class B heat tolerance, 3240 withstands the elevated operating temperatures of power-dense lithium systems without degradation.

Other Industrial Applications of 3240 Sheets

In addition to battery systems, 3240 sheets are widely used across various industries:

♦ Electric Motors and Generators: Rotor and stator slot insulation, coil end spacers

♦ Transformers: Core spacers, insulation gaskets, and structural support pieces

♦ Control Panels: Baseplates, busbar insulation, and terminal boards

♦ PCB Fixtures: Drilling plates and support for high-speed PCB processing

These applications benefit from the sheet’s consistent quality, machinability, and long-term stability even in humid or thermally challenging environments.

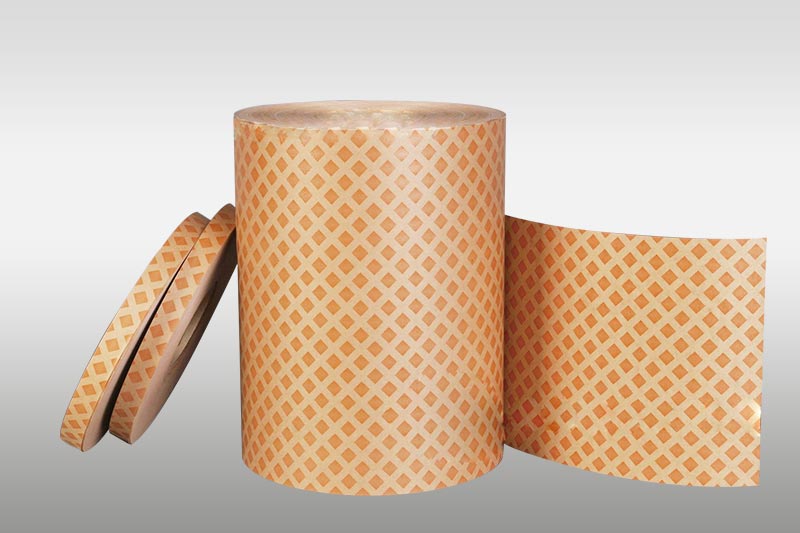

Customization and Processing Capabilities

3240 sheets are available in a wide range of thicknesses (from 0.5 mm to 50 mm) and can be easily CNC machined, punched, or cut into various shapes according to customer drawings. This flexibility allows manufacturers to reduce waste, streamline assembly, and improve product reliability.

Final Thoughts: Why Choose 3240?

For manufacturers looking for cost-effective yet high-performing insulation materials, 3240 epoxy resin sheets offer an optimal balance of electrical, mechanical, and thermal characteristics. Their adaptability across sectors—from renewable energy to industrial automation—ensures long-term value and operational safety.

Whether you're developing the next generation of lithium battery packs or building reliable power control systems, 3240 is a smart, scalable insulation solution worth considering.