Why FR4 Is the Preferred Material for Electrical and Electronic Insulation

In the world of electrical and electronic engineering, insulation materials are critical to ensuring device safety, reliability, and performance. Among the many insulating materials available today, FR4 has emerged as the industry favorite—particularly in applications like printed circuit boards (PCBs), electrical panels, and high-voltage equipment. But what makes FR4 so special? Let’s explore the core reasons why FR4 is the preferred material for electrical and electronic insulation.

What Is FR4?

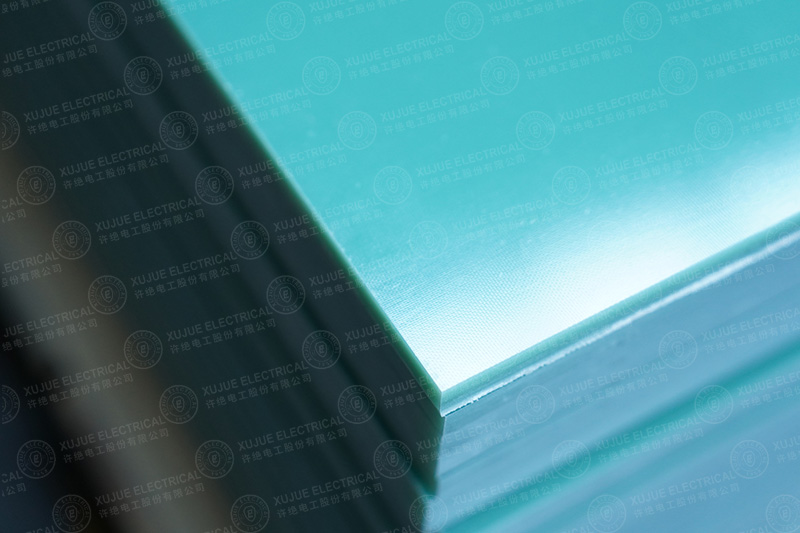

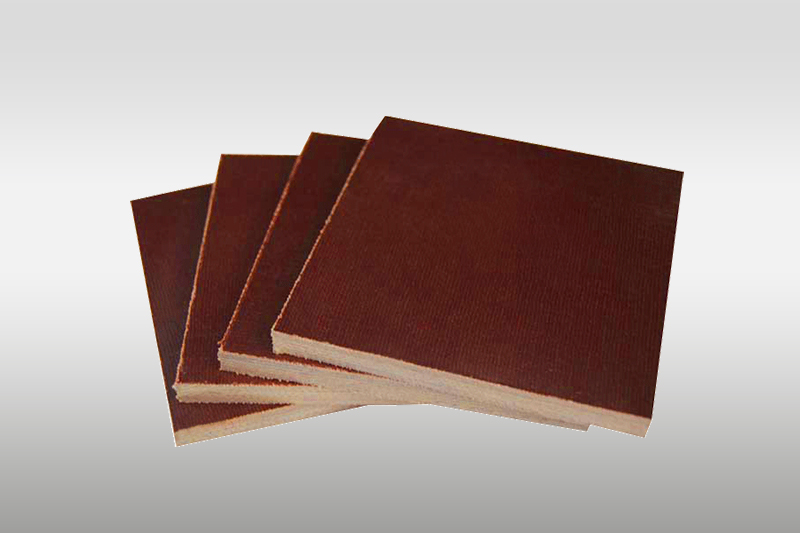

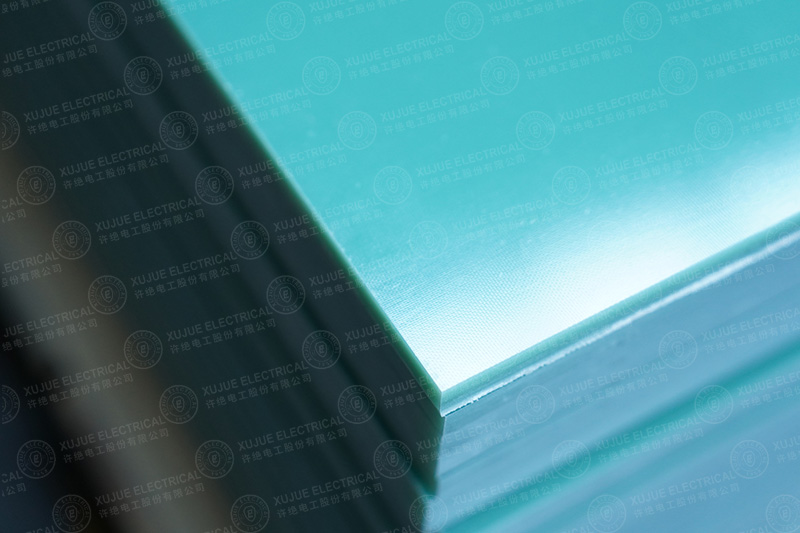

FR4 is a type of epoxy glass-reinforced laminate, made by layering woven fiberglass cloth with epoxy resin under heat and pressure. The result is a rigid, flame-retardant sheet with excellent electrical, mechanical, and thermal properties. The “FR” stands for Flame Retardant, and the “4” is a classification within the NEMA (National Electrical Manufacturers Association) standard.

Key Advantages of FR4 in Electrical Applications

1. Outstanding Electrical Insulation

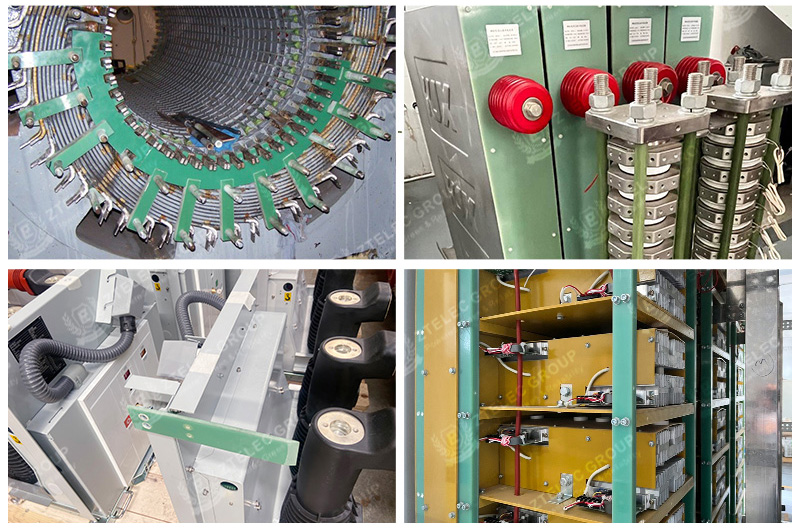

One of FR4’s most significant properties is its high dielectric strength and electrical resistivity, making it ideal for isolating electrical components without leakage or short circuits. This is essential in PCBs, transformers, and switchgear.

2. Flame Retardant Performance

FR4 is self-extinguishing and meets UL94-V0 flammability standards. This ensures safety in critical applications where fire prevention is a priority.

3. High Mechanical Strength

With excellent tensile and flexural strength, FR4 maintains its structural integrity under stress and load. It can be machined, drilled, or milled without cracking, making it suitable for complex design geometries.

4. Thermal Stability

FR4 can withstand temperatures up to 130°C continuously, making it suitable for electronic devices that generate heat. Enhanced versions can operate in even higher temperature ranges.

5. Moisture and Chemical Resistance

The epoxy resin matrix in FR4 resists moisture absorption, acids, and solvents—critical in outdoor or harsh environments like automotive, aerospace, and industrial control systems.

Where Is FR4 Used?

FR4 is incredibly versatile and widely used in:

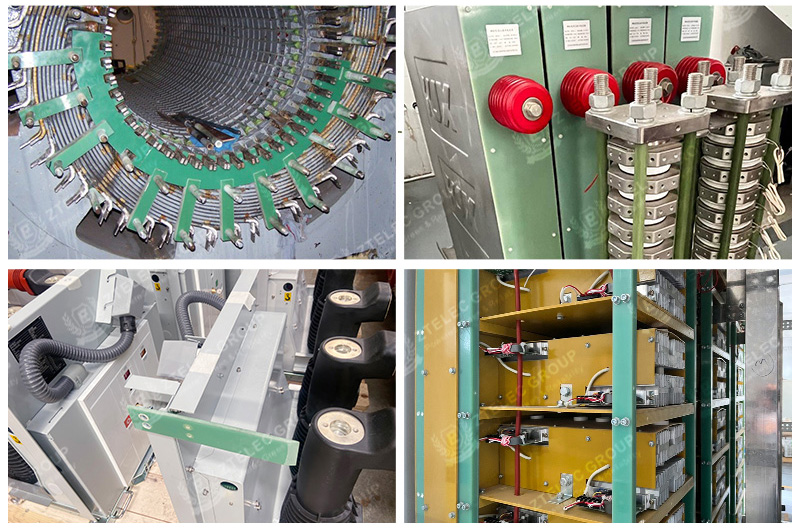

► Printed Circuit Boards (PCBs) – The most common application, forming the base material for electronic circuitry.

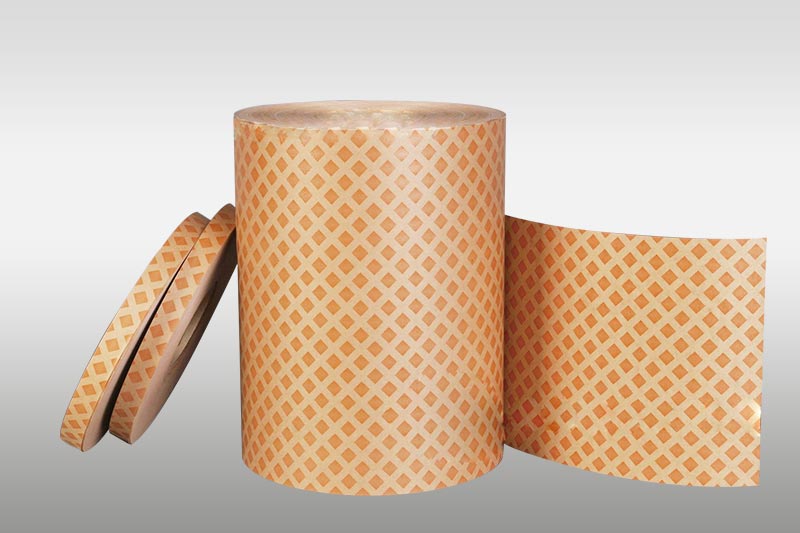

► Motor and Transformer Insulation – Providing stable insulation under electromagnetic stress.

► High-Voltage Switchgear and Busbars – As support panels and insulating spacers.

► Electrical Cabinets and Control Panels – For safe housing of relays, sensors, and control systems.

► Laser-Cut and CNC-Processed Insulating Components – Custom parts made from FR4 ensure precise fit and high reliability.

Cost-Effectiveness and Availability

Compared to advanced materials like ceramics or polyimide, FR4 offers an excellent cost-to-performance ratio. It is readily available, easy to process, and supports large-scale manufacturing without compromising quality.

Sustainability and Compliance

Leading FR4 suppliers like XuJue offer RoHS-compliant and ISO-certified FR4 materials. This ensures compatibility with global environmental and quality standards, making it a reliable choice for international clients.

Conclusion

FR4’s unique blend of electrical insulation, mechanical strength, thermal resistance, and flame retardancy positions it as the top choice for engineers and manufacturers alike. Whether you're building high-density PCBs or insulating high-voltage systems, FR4 provides the reliability and performance that modern electronics demand.

If you're looking for a trusted FR4 supplier, XuJue offers a full range of customizable FR4 solutions, including sheets, rods, CNC parts, and more—delivered globally with quality and precision.