FR4 Epoxy Laminated Board: Electrical Insulation Performance and Applications

Introduction

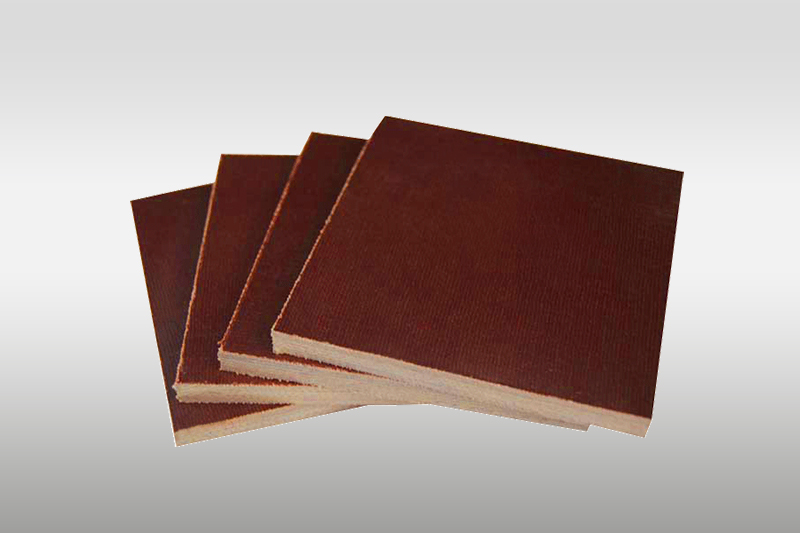

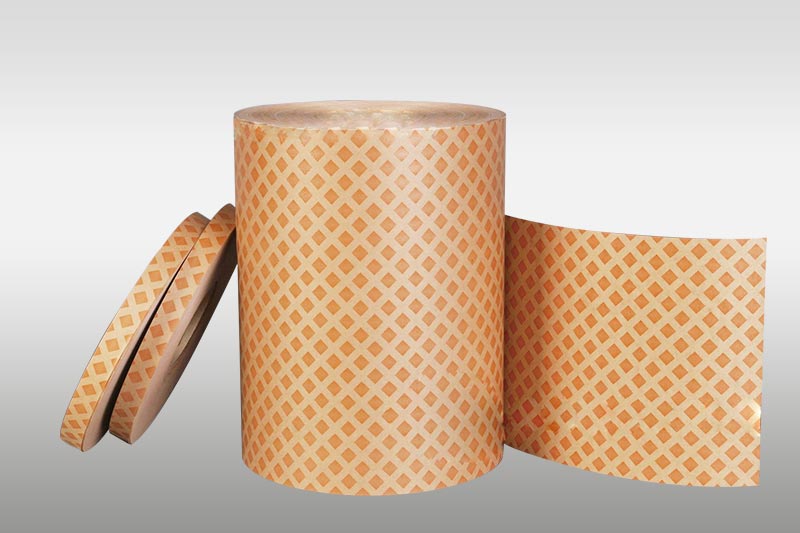

FR4 epoxy laminated board is one of the most widely used electrical insulation materials in the electronics and electrical industries. Produced from woven fiberglass cloth impregnated with epoxy resin, FR4 offers an excellent balance of mechanical strength, dielectric performance, flame resistance, and dimensional stability.

Because of these outstanding properties, FR4 has become the industry standard material for printed circuit boards (PCBs), motors, transformers, and a wide range of electrical equipment.

This article explores the electrical insulation performance of FR4 laminated sheets, their applications in motors and PCBs, and the international standards that ensure their reliability.

Electrical Insulation Performance of FR4

1. High Dielectric Strength

FR4 provides a dielectric strength of 16–20 kV/mm, ensuring reliable insulation between conductive layers or motor windings. This prevents electrical breakdown in high-voltage environments.

2. Excellent Insulation Resistance

With insulation resistance above 10¹² Ω, FR4 maintains stable electrical performance even in humid or high-moisture conditions.

3. Stable Dielectric Constant (Dk)

FR4 exhibits a dielectric constant of 4.2–4.8, supporting consistent signal integrity in PCBs and reducing signal distortion during transmission.

4. Low Dissipation Factor (Df)

Typically 0.015–0.020 at 1 MHz, FR4 provides reliable performance at higher frequencies, making it suitable for digital circuits and communication devices.

5. Flame Retardancy

The “FR” in FR4 stands for flame resistant. FR4 meets the UL94 V-0 classification, ensuring that the material self-extinguishes within 10 seconds without dripping, greatly improving safety.

1. Electrical Motors and Transformers

• Insulation Barriers: Used as slot liners, phase separators, and coil supports.

• Dielectric Protection: Prevents arcing and electrical faults between windings.

• Thermal Endurance: Operates reliably in Class B/F insulation systems (130–155°C).

• Mechanical Strength: Withstands vibration and mechanical stress in rotating machines.

2. Printed Circuit Boards (PCBs)

• Substrate Material: The standard base for single-layer, double-layer, and multilayer PCBs.

• Signal Reliability: Stable dielectric constant ensures minimal signal loss.

• Moisture Resistance: Low water absorption (<0.15%) guarantees long-term stability in humid environments.

• Cost-Effective: Balances electrical performance with affordability, making it the global PCB industry standard.

3. Other Electrical Applications

• Control panels

• Switchgear insulation parts

• Structural supports in electrical assemblies

International Standards for FR4 Laminated Boards

FR4 is recognized globally and tested against strict standards to guarantee safety and consistency:

NEMA LI 1-1998 – Defines FR4 as woven glass fabric with epoxy resin, flame-retardant.

UL94 V-0 – Flame retardancy classification.

IEC 60893 – International standard for industrial laminated sheets for electrical purposes.

IPC-4101 – Specifies performance and quality for PCB base materials.

RoHS & REACH – Ensures FR4 is free of hazardous substances, complying with environmental directives.

Conclusion

FR4 epoxy laminated board combines high dielectric strength, flame resistance, mechanical stability, and cost efficiency, making it the preferred insulation material in the global electronics and electrical industries.

Its widespread use in PCBs, motors, and transformers highlights its role as a reliable, safe, and standardized solution for modern electrical engineering.

For engineers and manufacturers, choosing FR4 ensures:

• Compliance with international safety standards

• Long-term insulation performance

• Cost-effective material selection