DDP Insulation Paper for Oil-Immersed Transformers: Properties and Applications

In modern power and distribution transformers, the choice of insulation material directly determines service life, efficiency, and reliability. Among the many insulation solutions available, Diamond Dotted Insulation Paper (DDP) has become one of the most trusted materials for oil-immersed transformers thanks to its excellent dielectric strength, adhesion, and thermal stability.

What is DDP Insulation Paper?

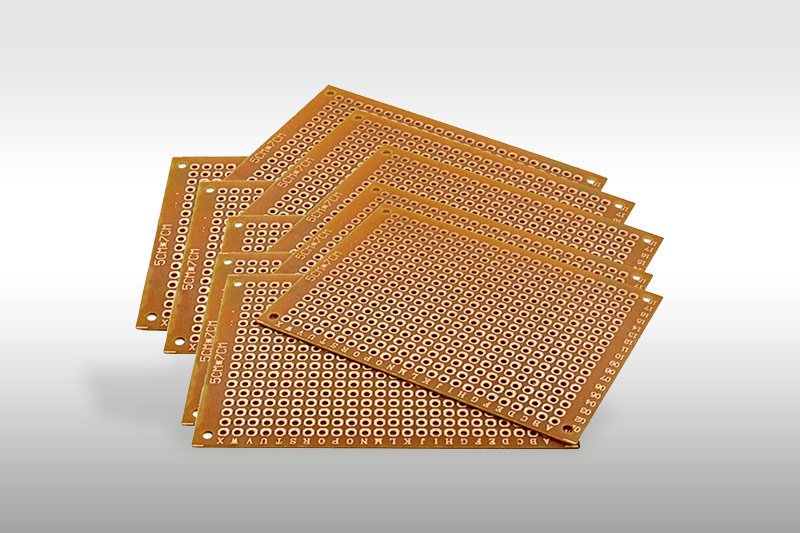

DDP insulation paper is a composite electrical insulation material consisting of high-quality cellulose base paper coated with epoxy resin adhesive in a diamond-shaped dotted pattern. During the transformer coil manufacturing process, these epoxy dots melt and bond under heat and pressure, firmly adhering adjacent layers together. This unique design prevents winding displacement, enhances structural stability, and ensures long-term insulation reliability.

Key Properties of DDP Insulation Paper

1. Superior Electrical Insulation

The cellulose insulation base paper provides outstanding dielectric properties, minimizing the risk of electrical breakdown.

2. Reliable Adhesion

The diamond-shaped epoxy coating softens and bonds during hot pressing, ensuring firm adhesion between layers and preventing conductor movement.

3. Enhanced Mechanical Strength

Once cured, DDP insulation paper significantly improves the rigidity of transformer windings, protecting them from deformation under short-circuit forces.

4. Excellent Oil Compatibility

As a specialized oil immersed transformer insulation material, DDP demonstrates strong compatibility with insulating oil, maintaining stability and performance throughout the transformer’s lifespan.

5. Thermal Resistance

DDP can withstand high operating temperatures, ensuring consistent insulation performance under demanding conditions.

Applications in Oil-Immersed Transformers

DDP insulation paper is widely used as turn insulation and layer insulation in transformer windings. Its role is crucial in multiple aspects:

• Electrical Insulation: Prevents electrical contact between adjacent turns and layers.

• Structural Reinforcement: Increases the mechanical stability of coils, especially under fault conditions.

• Thermal Stability: Maintains insulation performance under the heat generated during transformer operation.

• Design Efficiency: Its thin yet strong insulation layer allows compact winding structures, optimizing transformer size and performance.

In oil immersed power transformers, these benefits translate into longer service life, improved reliability, and reduced operational risks, making DDP a preferred choice among transformer manufacturers worldwide.

Conclusion

With the growing demand for efficient and durable power equipment, DDP insulation paper has become an essential insulation material in oil-immersed transformers. Its combination of dielectric strength, adhesive properties, and mechanical reinforcement ensures that transformers deliver safe and stable performance for decades.

For manufacturers and users alike, choosing high-quality DDP insulation paper suppliers is key to ensuring transformer reliability, energy efficiency, and long-term cost savings.