DDP Insulation Paper for Oil-Immersed Transformers

Introduction

In the power industry, oil-immersed transformers are widely used for power transmission and distribution because of their stable performance and excellent cooling ability. One of the most important factors in ensuring the long service life and safety of these transformers is the quality of insulation materials. Among them, DDP Insulation Paper (Diamond Dotted Paper) has become a key material due to its unique epoxy coating design and reliable electrical performance.

According to industry statistics, insulation failures account for more than 40% of transformer faults, and the use of high-quality insulation materials such as DDP paper significantly reduces the risk of breakdowns and extends transformer lifespan.

What is DDP Insulation Paper?

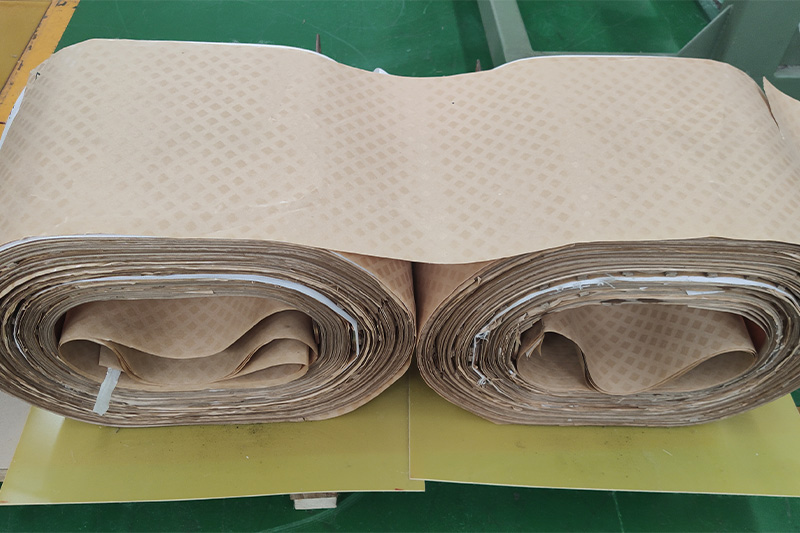

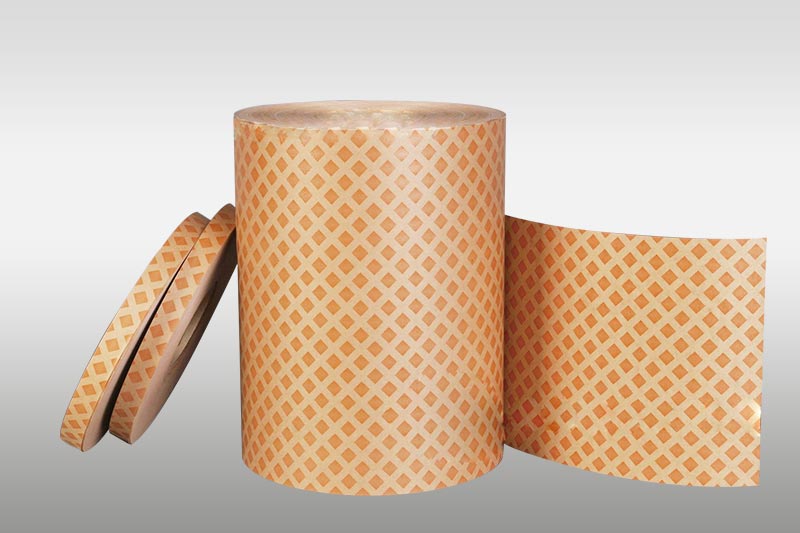

DDP (Diamond Dotted Paper) is manufactured from high-purity electrical insulating paper coated with epoxy resin in a diamond-shaped pattern. The resin is semi-cured (B-stage), allowing it to bond tightly under heat and pressure during the transformer winding process.

This structure not only enhances dielectric performance but also provides mechanical adhesion, ensuring the insulation layers remain stable throughout the transformer’s operational life.

1. High Electrical Strength

• Dielectric strength typically reaches 60 – 70 kV/mm, effectively preventing electrical breakdown between windings.

2. Strong Bonding Capability

• The diamond-shaped epoxy resin softens during coil drying and hot pressing, bonding firmly with conductors and adjacent insulation layers.

3. Thermal Class & Stability

• DDP insulation paper generally meets Class A (105℃) insulation requirements, suitable for long-term operation in oil-filled transformers.

4. Excellent Oil Impregnation

• Allows complete impregnation by transformer oil, improving long-term insulation stability and partial discharge resistance.

5. Moisture Resistance

• Maintains dielectric properties even under humid storage or operational conditions.

Applications in Oil-Immersed Transformers

DDP insulation paper is widely applied in the internal insulation structure of transformers, particularly medium and high-voltage oil-immersed transformers. Typical applications include:

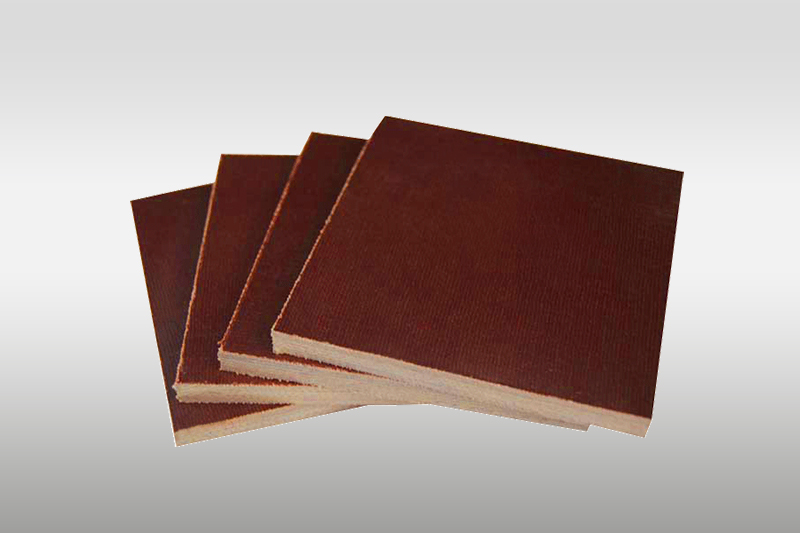

• Turn-to-Turn Insulation: Prevents electrical contact between adjacent winding turns.

• Layer Insulation: Used between coil layers to ensure dielectric safety.

• End Insulation: Protects winding ends, reducing edge electrical stress.

• Spacer Material: Provides mechanical support and prevents winding displacement during short-circuit forces.

By using DDP insulation paper, transformer manufacturers can achieve:

• Improved winding stability during coil assembly and curing.

• Extended transformer service life, often exceeding 20–30 years in stable operation.

• Enhanced safety under overload or voltage fluctuation conditions.

Industry Advantages

Compared with traditional plain insulating paper, DDP paper offers 30–50% higher bonding strength due to its epoxy resin coating. This improvement directly translates into:

• Lower partial discharge probability in transformer windings.

• Better mechanical endurance during sudden short-circuit forces.

• Reduced maintenance costs over the entire service cycle.

Because of these benefits, DDP insulation paper is now a standard choice for many power transformer factories, reactor manufacturers, and electrical equipment producers worldwide.

Conclusion

DDP Insulation Paper plays a vital role in the insulation system of oil-immersed transformers. Its combination of high dielectric strength, excellent oil impregnation, strong adhesion, and thermal stability ensures long-term reliability of transformer operation.

As the demand for stable, efficient, and long-life transformers continues to grow globally, DDP insulation paper will remain one of the most indispensable materials in transformer manufacturing and maintenance.