Transformer Insulation Paper: Types, Applications, and Selection Guide

Introduction

Insulation paper is critical to the reliability and performance of transformers and other electrical equipment. With excellent dielectric properties, mechanical strength, and thermal stability, insulation paper ensures long-term safety of transformer windings. This article explores the types of insulation paper, their applications in transformers, and practical guidance on how to select the right material for your project.

Types of Insulation Paper

1. Kraft Insulation Paper

Kraft insulation paper, made from high-purity cellulose fibers, is widely used in oil-immersed transformers. It offers good electrical insulation, mechanical strength, and cost-effectiveness, making it one of the most popular choices in the transformer industry.

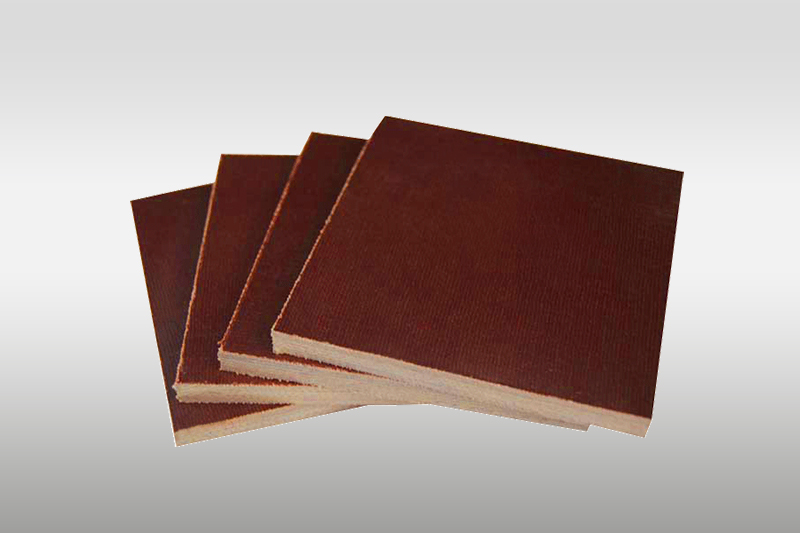

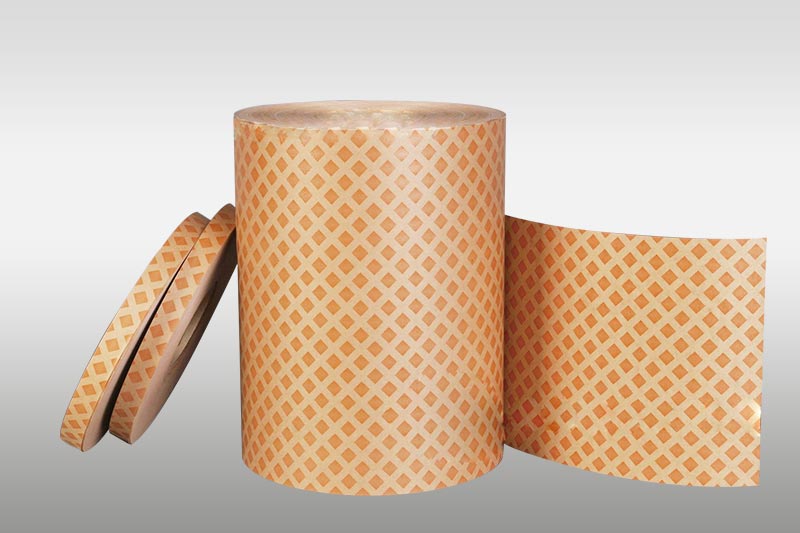

2. Diamond Dotted Insulation Paper (DDP)

Diamond dotted insulation paper for transformer windings is coated with diamond-shaped epoxy resin. When heated, the resin melts and bonds firmly with conductor surfaces, ensuring strong adhesion, mechanical stability, and excellent partial discharge resistance in high-voltage transformers.

3. Aramid Insulation Paper

Aramid insulation paper with high thermal resistance (Class H, 180°C) is designed for applications that require long-term durability and reliability. It is commonly used in motors, generators, and dry-type transformers, where superior heat resistance and safety are essential.

4. Composite Insulation Paper

Composite insulation paper for power transformers combines cellulose with polyester film, epoxy resin, or aramid fibers to improve dielectric strength, mechanical durability, and flexibility. It is suitable for demanding insulation structures that require both toughness and reliability.

Applications of Insulation Paper in Transformers

Oil-immersed transformers → Kraft insulation paper and DDP provide reliable insulation stability in liquid-filled environments.

Dry-type transformers → Epoxy-coated insulation paper enhances bonding strength and mechanical integrity.

High- and low-voltage windings → Transformer insulation paper for HV & LV windings minimizes short-circuit risks and improves overall safety.

Motors and generators → Electrical insulation paper for motors and generators ensures dependable coil-to-coil insulation.

Selection Guide: How to Choose the Right Insulation Paper

When choosing insulation paper, consider the following factors:

Thermal class → Select high temperature insulation paper (e.g., aramid insulation paper) for high-demand environments.

Application environment → For oil-immersed transformers, kraft and DDP papers are standard; for dry-type transformers, epoxy-coated insulation paper is preferred.

Mechanical strength → If high tensile strength is required, composite insulation paper is the best option.

Cost efficiency → Kraft insulation paper offers an economical solution, while aramid insulation paper provides premium performance for critical applications.

Conclusion

Insulation paper remains one of the most essential materials for transformer and electrical insulation systems. Whether you need kraft insulation paper for oil-immersed transformers, diamond dotted insulation paper for transformer windings, or aramid insulation paper high thermal resistance, selecting the right type ensures safety, efficiency, and long service life.

If you are looking for a trusted insulation paper supplier for transformers, ZTelec provides high-quality, customized insulation materials tailored to your specific needs.