Epoxy Fiberglass Winding Tube for OLTC | Reliable Insulation for Oil-Immersed Transformers

In modern power transformers, reliability and safety are the top priorities for electrical engineers and manufacturers. Among all internal components, the on-load tap changer (OLTC) plays a crucial role in maintaining voltage stability by adjusting the turns ratio of the transformer while it is energized. Because the OLTC operates under load and within oil-filled environments, the insulation system must be capable of withstanding continuous mechanical, electrical, and thermal stresses.

One of the key materials used in OLTC assemblies is the Epoxy Fiberglass Winding Tube — a high-performance composite designed to deliver exceptional insulation, strength, and durability.

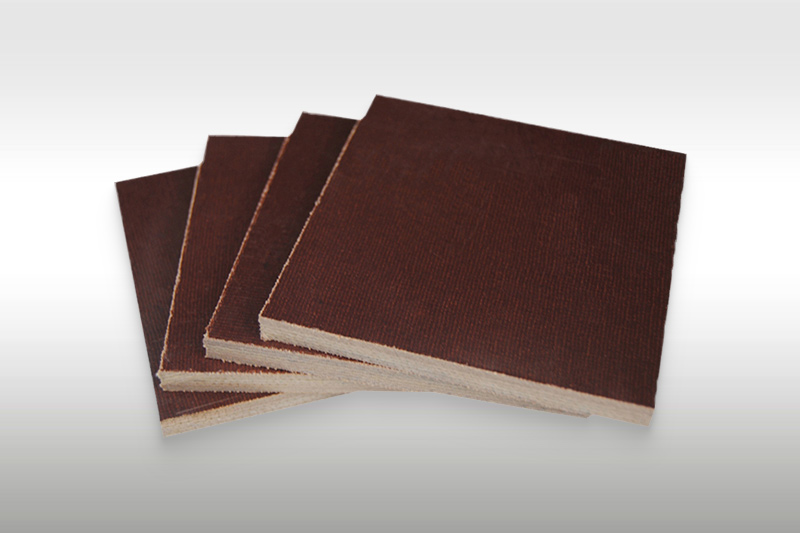

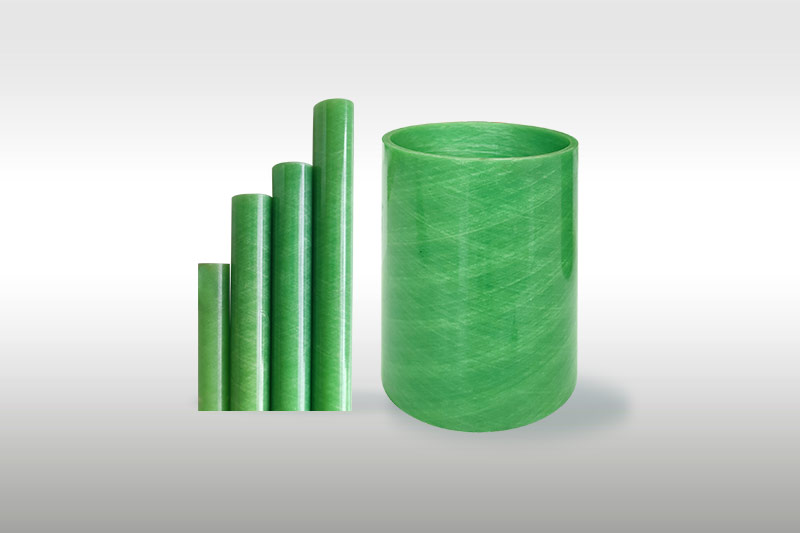

The Epoxy Fiberglass Winding Tube for OLTC combines the benefits of epoxy resin and woven fiberglass cloth, resulting in a material with superior dielectric and mechanical properties. These tubes are precision-processed through a filament winding or rolling technique, followed by high-temperature curing to achieve excellent dimensional stability.

• High Dielectric Strength: Ensures safe switching under high voltage and transient conditions.

• Superior Mechanical Stability: Withstands torque, vibration, and repetitive mechanical stress during tap changing operations.

• Outstanding Oil Resistance: Resists transformer oil degradation, preventing swelling or delamination.

• Excellent Thermal Endurance: Maintains performance under high operating temperatures and heavy load fluctuations.

Performance in Oil-Immersed Transformer Environments

Inside oil-immersed transformers, insulation components are exposed to mineral or ester-based insulating oils. This environment demands materials that are chemically stable and non-reactive to oil aging byproducts.

XuJue Epoxy Fiberglass Winding Tubes are engineered to maintain dielectric integrity and mechanical strength even after thousands of thermal cycles. Their low moisture absorption and excellent adhesion between resin and glass fibers further enhance performance consistency.

The precision of the winding process ensures tight dimensional tolerance, critical for maintaining uniform electrical clearances in OLTC assemblies.Customization and Processing Capabilities

XuJue provides customizable epoxy fiberglass winding tubes to meet specific OLTC and transformer design requirements. Tubes can be supplied in different:

• Inner/outer diameters

• Wall thicknesses

• Lengths

• Machined configurations (slots, holes, grooves, threading)

Advanced CNC machining and strict quality control ensure high dimensional accuracy, compatible with customers’ transformer assembly processes.

Enhancing Transformer Reliability and Lifespan

The quality of insulation components directly affects transformer lifespan. Using high-grade epoxy fiberglass winding tubes minimizes insulation failures, partial discharges, and mechanical wear within OLTC systems.

By integrating XuJue Epoxy Fiberglass Winding Tubes, manufacturers benefit from:

• Improved electrical reliability

• Reduced maintenance costs

• Extended transformer service life

Ultimately, these tubes contribute to more stable voltage regulation and enhanced power system efficiency.

Conclusion

The Epoxy Fiberglass Winding Tube for On-Load Tap Changers is not just a structural component—it’s a critical part of the transformer’s insulation system. With excellent electrical, mechanical, and oil-resistant properties, XuJue’s epoxy fiberglass tubes ensure safe, long-lasting performance for oil-immersed transformers worldwide.

If you’re seeking a trusted insulation material supplier for OLTC applications, XuJue Electrical delivers precision-engineered solutions that meet global transformer standards.