Application Guidelines for Red Epoxy Resin Pre-impregnated DMD

Introduction

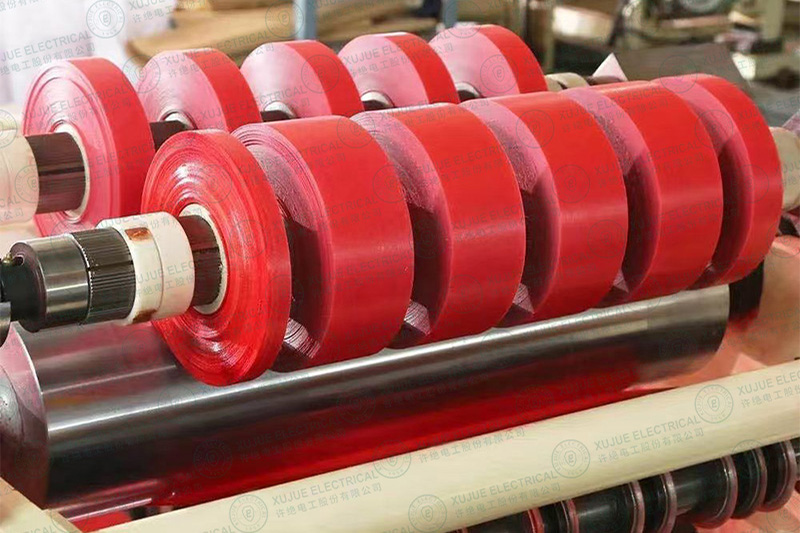

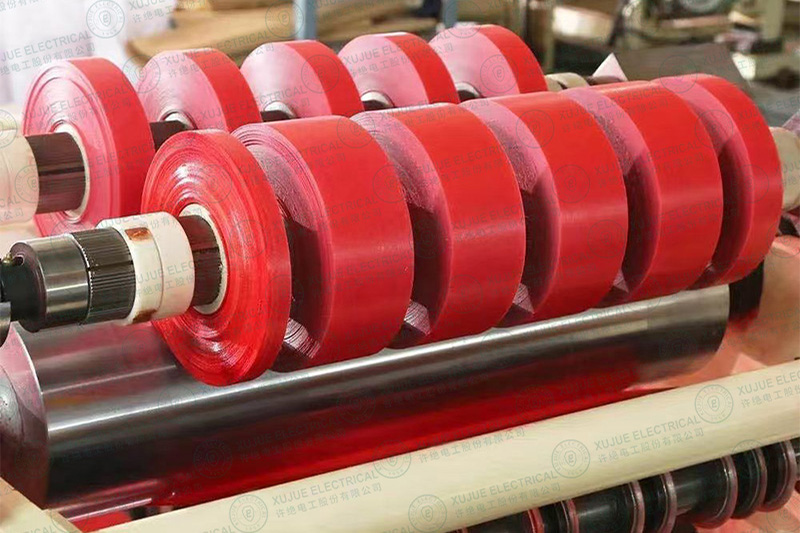

Red Epoxy Resin Pre-impregnated DMD is a high-performance flexible composite insulation material widely used in the manufacturing of electric motors, transformers, and generators.It is made by combining a polyester film (Mylar) with two layers of composite nonwoven fabric pre-impregnated with a specially formulated epoxy resin. After baking and curing, the resin forms a stable, tough, and heat-resistant insulation system.

This material combines excellent mechanical strength, dielectric properties, and heat resistance, making it an essential choice for dry-type transformers and motor insulation applications.

1. Structure and Properties

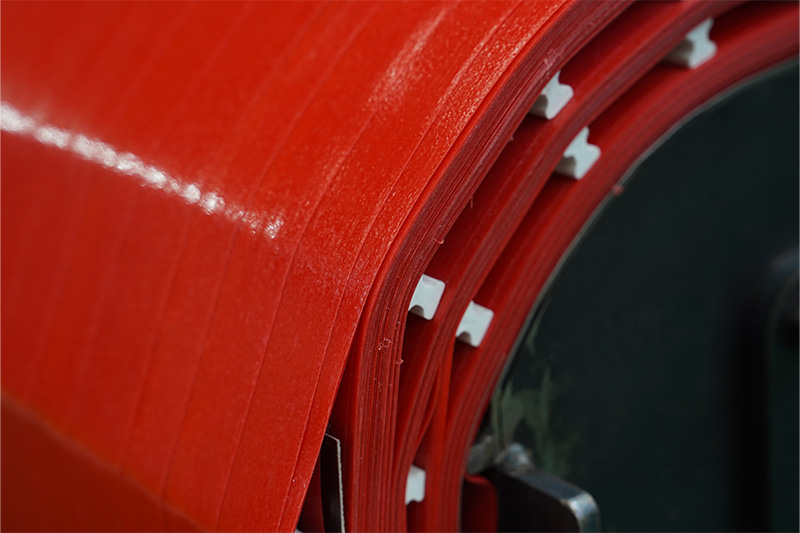

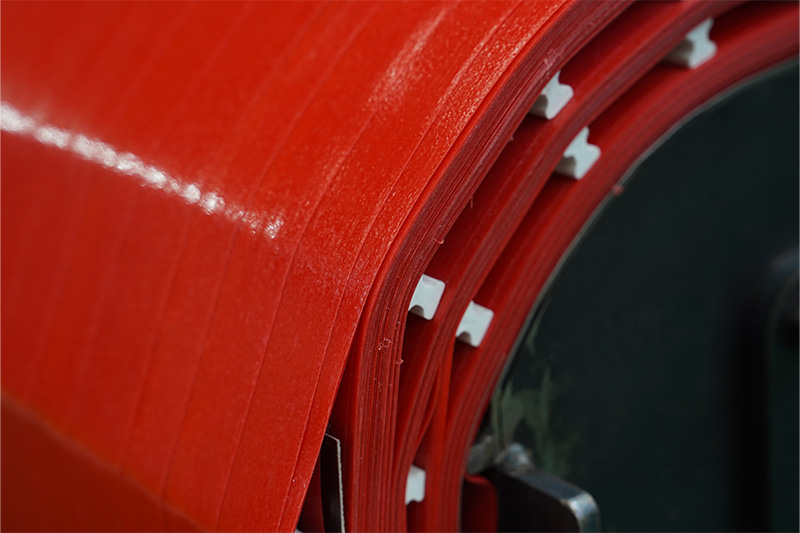

Red Epoxy Resin Prepreg DMD (also known as Epoxy Prepreg DMD Insulation Paper) consists of three layers:

• Outer Layers: High-quality polyester non-woven fabric ensures flexibility and mechanical support.

• Core Layer: Polyester film provides excellent dielectric strength and dimensional stability.

• Epoxy Resin Coating: Pre-impregnated epoxy enhances bonding, adhesion, and heat resistance after curing.

Key Properties:

• Thermal class: Class F (155°C) or higher.

• Good dielectric strength and breakdown voltage.

• Excellent bonding ability after heat curing.

• High mechanical strength and resistance to tearing.

• Good compatibility with transformer oil and varnishes.

2. Typical Applications

Red Epoxy Resin Pre-impregnated DMD is primarily used as slot insulation, interturn insulation, and layer insulation in electrical machines.

Common applications include:

Electric Motors: Used for slot liners, slot wedges, and phase insulation. After hot pressing, the resin cures to form a rigid and compact insulation layer that withstands thermal and mechanical stress.

Transformers: Applied between winding layers or as interlayer insulation in both dry-type and oil-immersed transformers.

Generators and Reactors: Provides thermal stability and excellent dielectric separation in high-voltage coils.

Other Electrical Equipment: Suitable for reactors, coils, and insulation barriers requiring firm adhesion and high voltage endurance.

3. Processing and Handling Guidelines

To achieve optimal performance, proper processing and curing are essential.

(1) Storage:

• Store in a cool, dry, and ventilated place below 25°C.

• Avoid direct sunlight and humidity.

• Shelf life is typically 6 months under recommended conditions.

(2) Cutting and Forming:

• Cut the material to desired sizes before heating.

• Handle gently to avoid contamination or surface damage.

(3) Molding and Curing:

• Place the prepreg material in the designed slot or mold area.

• Apply uniform pressure and heat.

• Typical curing condition: 130–150°C for 2–3 hours, depending on the thickness and resin content.

• After curing, the material becomes rigid with high bonding strength and excellent insulation properties.

(4) Safety Precautions:

• Avoid direct contact with skin during hot pressing.

• Use protective gloves and ensure good ventilation during heating.

4. Advantages of Using Epoxy Prepreg DMD

• Enhanced Insulation Reliability: The epoxy resin bonds tightly, minimizing air gaps and improving dielectric stability.

• Improved Mechanical Integrity: After curing, it forms a unified insulation structure with strong adhesion between layers.

• High Thermal Resistance: Suitable for Class F and H insulation systems.

• Moisture and Oil Resistance: Performs well in humid environments and transformer oil conditions.

• Easy Processing: Can be directly molded and cured without additional varnishing steps.

5. Conclusion

Red Epoxy Resin Pre-impregnated DMD is an advanced insulation material designed to meet the increasing demands of modern electrical equipment. With excellent electrical, thermal, and mechanical properties, it provides reliable insulation protection for motors, transformers, and other high-voltage systems.

For manufacturers seeking consistent quality and performance, using high-grade Red Epoxy Resin Prepreg DMD ensures stable production, enhanced insulation reliability, and longer service life of electrical devices.