Flame Retardant FR4 Sheet for Industrial Electrical Insulation

Introduction

In industrial electrical systems, insulation materials must meet strict requirements for fire safety, electrical reliability, and long-term mechanical stability. Flame Retardant FR4 Sheet is one of the most widely used insulation materials in the electrical and electronics industry, trusted for its excellent dielectric performance, flame resistance, and structural strength. As a glass-fiber reinforced epoxy laminate, FR4 plays a critical role in ensuring safe and stable operation of power equipment and electrical assemblies.

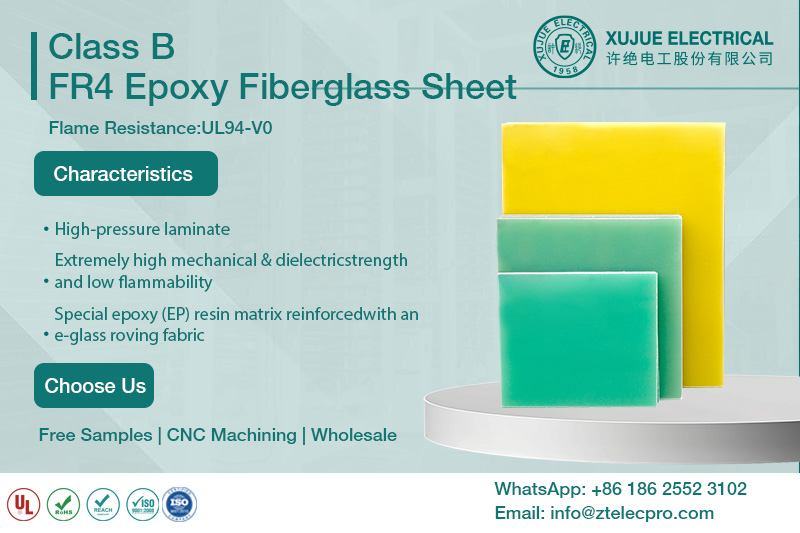

What Is Flame Retardant FR4 Sheet?

Flame Retardant FR4 Sheet is manufactured by impregnating woven fiberglass cloth with flame-retardant epoxy resin, followed by high-temperature and high-pressure lamination. The “FR” designation refers to flame retardancy, meaning the material meets recognized fire safety standards such as UL 94 V-0, where the material self-extinguishes after ignition.

Compared with standard epoxy laminates, FR4 epoxy fiberglass sheets offer a superior balance of electrical insulation, thermal resistance, and fire safety, making them suitable for industrial and commercial electrical applications.

Key Electrical and Mechanical Properties of FR4

FR4 electrical insulation sheets are engineered to perform reliably under demanding industrial conditions:

• High Dielectric Strength

FR4 provides excellent insulation performance, making it suitable for medium- and high-voltage electrical equipment.

• UL94 V-0 Flame Retardancy

Flame retardant FR4 sheets significantly reduce fire risk in electrical systems and comply with international safety standards.

• Strong Mechanical Properties

Reinforced with fiberglass, FR4 sheets offer high flexural strength, impact resistance, and dimensional stability.

• Thermal Stability

Standard FR4 materials operate at 130°C (Thermal Class B), while high-Tg FR4 grades can withstand higher continuous temperatures.

• Moisture and Chemical Resistance

FR4 epoxy glass laminates maintain stable insulation performance even in humid or chemically exposed environments.

Industrial Applications of Flame Retardant FR4 Sheet

Due to its comprehensive performance, FR4 is widely used in various industrial electrical insulation applications:

Electrical Panels and Switchgear

Used as insulation barriers, mounting plates, and support structures.

Transformers and Power Equipment

Applied in insulation components, terminal boards, and structural supports.

Industrial Control Cabinets

FR4 sheets are CNC machined into custom insulation parts for inverters, drives, and power distribution systems.

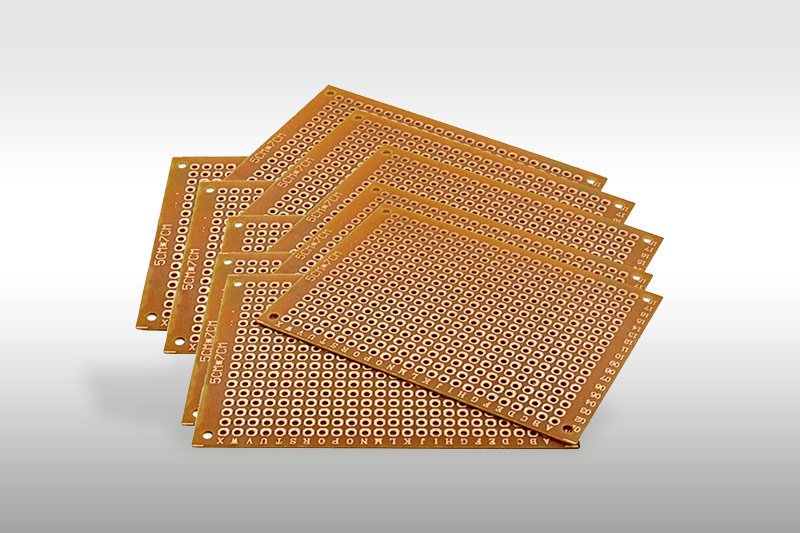

Printed Circuit Boards (PCBs)

FR4 epoxy fiberglass laminate is the most common substrate material for rigid PCBs.

CNC Machined FR4 Insulation Parts

Including spacers, gaskets, brackets, and insulation supports for motors and generators.

Advantages of FR4 Over Other Insulation Materials

Compared to phenolic sheets, polyester laminates, or paper-based insulation, flame retardant FR4 sheets offer better fire resistance, higher mechanical strength, and more stable electrical performance. FR4 is also well suited for precision CNC machining, allowing manufacturers to meet complex design and tolerance requirements without compromising insulation quality.

Conclusion

Flame Retardant FR4 Sheet is a reliable and cost-effective solution for industrial electrical insulation, combining UL94 V-0 fire resistance, excellent dielectric properties, and mechanical durability. Whether used in electrical panels, transformers, control cabinets, or CNC-machined insulation parts, FR4 epoxy fiberglass sheets continue to be a benchmark material for modern electrical engineering.