EPGC 308 Epoxy Glass Laminate: A Reliable Alternative to Standard FR4 for Industrial Applications

In the field of electrical insulation and industrial structural materials, epoxy glass laminates play a critical role in ensuring safety, durability, and long-term performance. While FR4 is widely known and commonly used, it is not always the optimal choice for demanding industrial applications.

EPGC 308 epoxy glass laminate is increasingly selected by engineers and procurement professionals who require higher mechanical strength, better dimensional stability, and more reliable machining performance.

This article provides a detailed overview of EPGC 308, its key properties, advantages, and typical applications, helping you make an informed material selection.

What Is EPGC 308?

EPGC 308 is an epoxy resin–bonded glass fabric laminated sheet manufactured in accordance with IEC 60893 standards. It is produced by impregnating high-strength glass fabric with epoxy resin and laminating it under controlled heat and pressure.

Although EPGC 308 and FR4 share a similar epoxy-glass material system, EPGC 308 is engineered specifically for industrial insulation and structural applications, rather than printed circuit boards.

In practical terms, EPGC 308 offers:

► Enhanced mechanical performance

► Improved thermal and dimensional stability

► Greater consistency in industrial machining operations

Key Performance Advantages of EPGC 308

1. High Mechanical Strength

EPGC 308 exhibits excellent flexural strength, tensile strength, and impact resistance. It performs reliably under continuous mechanical load, making it suitable for structural insulation components.

Compared with standard FR4, EPGC 308 is less prone to cracking, deformation, or fatigue failure in long-term service.

2. Superior Dimensional Stability

Dimensional stability is critical in applications involving CNC machining, tight tolerances, and elevated temperatures.

EPGC 308 maintains stable dimensions during processing and operation, reducing risks such as:

► Warping

► Delamination

► Thickness deviation

This stability improves assembly accuracy and product consistency.

3. Reliable Electrical Insulation Performance

EPGC 308 provides stable dielectric strength and insulation resistance, making it suitable for medium- and high-voltage electrical environments.

It is commonly used in electrical equipment where insulation reliability must be maintained over long service periods.

4. Excellent Machinability

From a manufacturing perspective, EPGC 308 offers clean cutting edges, low fiber pull-out, and minimal delamination during machining.

For fabricators and OEMs, this results in:

► Higher yield rates

► Lower rejection and rework costs

► More consistent finished parts

EPGC 308 vs. FR4: Key Differences

|

Property |

FR4 |

EPGC 308 |

|

Primary Application |

PCB & general insulation |

Industrial structural insulation |

|

Mechanical Strength |

Moderate |

High |

|

Dimensional Stability |

Standard |

Superior |

|

Long-term Load Resistance |

Limited |

Excellent |

|

CNC Machining Reliability |

Acceptable |

Preferred |

When the application involves mechanical stress, structural support, or long-term reliability, EPGC 308 is often the more suitable material.

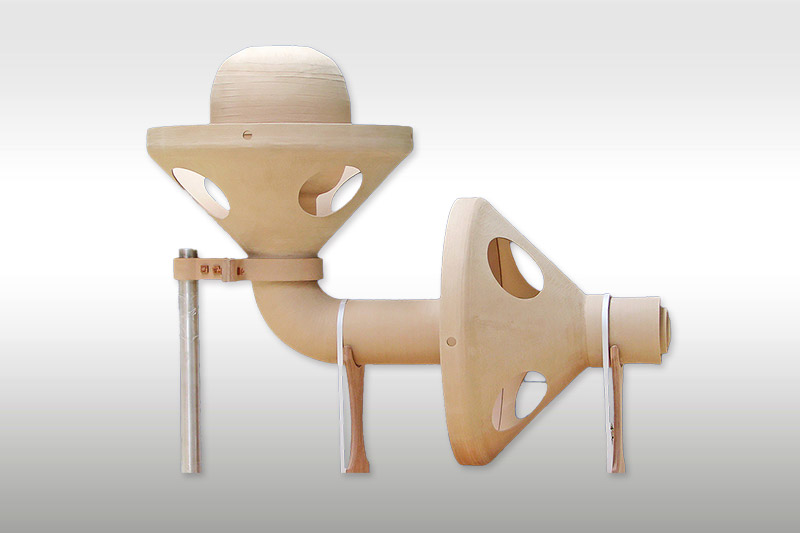

Typical Applications of EPGC 308

EPGC 308 epoxy glass laminates are widely used in:

► Electric motors and generators

► Dry-type and oil-immersed transformers

► High-voltage electrical equipment

► Industrial insulation components

► CNC-machined epoxy insulation parts

Material Selection Recommendations

EPGC 308 is strongly recommended if your project requires:

► Higher mechanical strength than standard FR4

► Stable performance during machining

► Long-term dimensional reliability

► Electrical insulation combined with structural support

Conclusion

FR4 remains a versatile and widely used material, but it is not always the best choice for industrial insulation applications.

EPGC 308 epoxy glass laminate offers a balanced combination of mechanical strength, electrical insulation, and machining stability, making it a reliable solution for demanding industrial environments.

For engineers, QA teams, and procurement professionals seeking consistent quality and long service life, EPGC 308 is a material worth serious consideration.