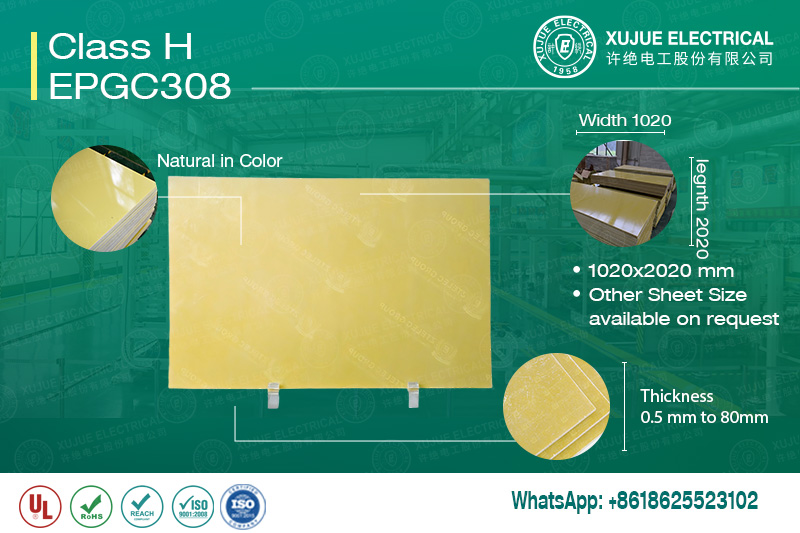

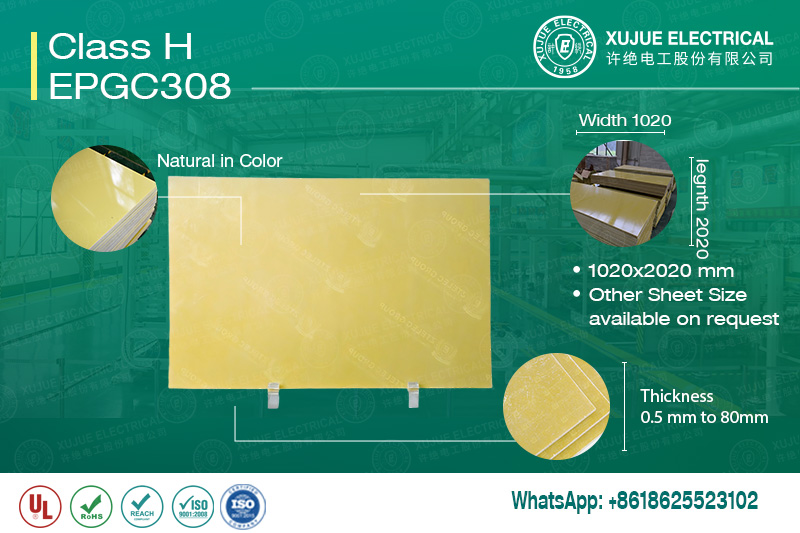

EPGC308 Epoxy Glass Laminate: A Reliable Structural Insulation Material for Electrical Engineering

In electrical equipment design, insulation materials are expected to perform far beyond basic electrical separation. They must withstand mechanical stress, thermal cycling, and long-term electrical loads while maintaining dimensional stability. EPGC308 epoxy glass laminate is widely used in power and electromechanical systems for precisely these reasons.

At XuJue, EPGC308 is supplied and machined as a structural electrical insulation material, engineered to meet the real-world demands of transformers, motors, generators, and switchgear.

Material Structure and Engineering Significance

EPGC308 is a thermoset epoxy laminate reinforced with woven glass fiber. Through high-temperature and high-pressure curing, the material forms a dense and uniform structure with excellent bonding between resin and glass cloth.

From an engineering standpoint, this structure delivers:

• High dielectric strength for stable insulation performance

• Strong mechanical integrity for load-bearing insulation parts

• Consistent properties across thickness and surface area

This makes EPGC308 suitable not only as an insulating barrier, but as a functional structural component within electrical assemblies.

Electrical and Mechanical Performance

In operational environments, insulation materials must handle simultaneous electrical and mechanical stress. EPGC308 performs reliably under such conditions.

Key performance characteristics include:

• Stable insulation resistance under continuous voltage

• Low dielectric loss in electrical applications

• High tensile and flexural strength

These properties allow engineers to integrate EPGC308 into components that maintain electrical safety while supporting mechanical loads during operation and assembly.

Typical Applications in Electrical Equipment

EPGC308 is commonly used in a wide range of electrical systems.

In transformers, it is applied in:

• Insulating spacers and support blocks

• Clamping and structural insulation parts

In motors and generators, EPGC308 is used for:

• End winding supports

• Insulating brackets and frames

In switchgear and power distribution equipment, typical uses include:

• Busbar supports

• Phase separation panels

• Structural insulation boards

These applications benefit from the material’s balance of electrical reliability and mechanical stability.

Machining and Custom Insulation Components

One of the major advantages of EPGC308 is its excellent machinability. It is well suited for CNC processing, allowing manufacturers to produce complex insulation components with high dimensional accuracy.

At XuJue, EPGC308 is routinely machined into:

• Precision insulation parts

• Custom structural components

• Application-specific electrical insulation solutions

Clean cutting edges and stable tolerances make EPGC308 ideal for both prototyping and production-level manufacturing.

Reliability in Long-Term Service

Electrical equipment is designed for long service life, often operating continuously for years. EPGC308 demonstrates strong resistance to aging, deformation, and mechanical fatigue, helping maintain insulation performance throughout the equipment lifecycle.

For engineers, this reliability translates into:

• Reduced maintenance risk

• Improved operational safety

• Stable performance under thermal and electrical cycling

Conclusion

EPGC308 epoxy glass laminate is a proven solution for structural electrical insulation applications where mechanical strength and dielectric reliability are equally important. Its material structure, machining adaptability, and long-term stability make it a dependable choice in modern electrical engineering.

With experience in insulation materials and precision machining, XuJue provides EPGC308 solutions tailored to the technical requirements of power and electrical equipment manufacturers worldwide.