G10 vs FR4 vs G11 vs FR5: Understanding the Real Temperature Difference in Epoxy Glass Laminates

When selecting the right insulation materials for motors, transformers, switchgear, or industrial equipment, the temperature resistance of epoxy glass laminates becomes one of the most important considerations. Among the most commonly used grades—G10, FR4, G11, and FR5—the differences in thermal properties directly affect product reliability, service life, and safety.

In this article, we break down each material’s composition, thermal performance, and recommended application so you can make the right choice based on your project’s temperature requirements.

1. Material Overview: G10, FR4, G11, FR5

G10 – Standard Epoxy Glass Laminate

G10 – Standard Epoxy Glass Laminate

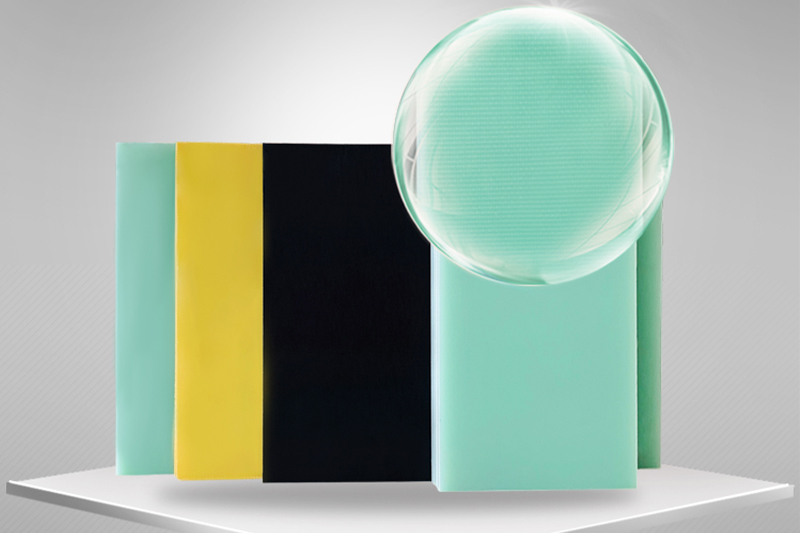

G10 is an electrical-grade epoxy laminate made from woven fiberglass cloth and epoxy resin.

It offers:

► Good mechanical strength

► Stable dielectric performance

► Designed for normal temperature applications

FR4 – Flame-Retardant Version of G10

FR4 – Flame-Retardant Version of G10

FR4 contains a flame-retardant additive, giving it UL94-V0 performance while maintaining properties similar to G10.

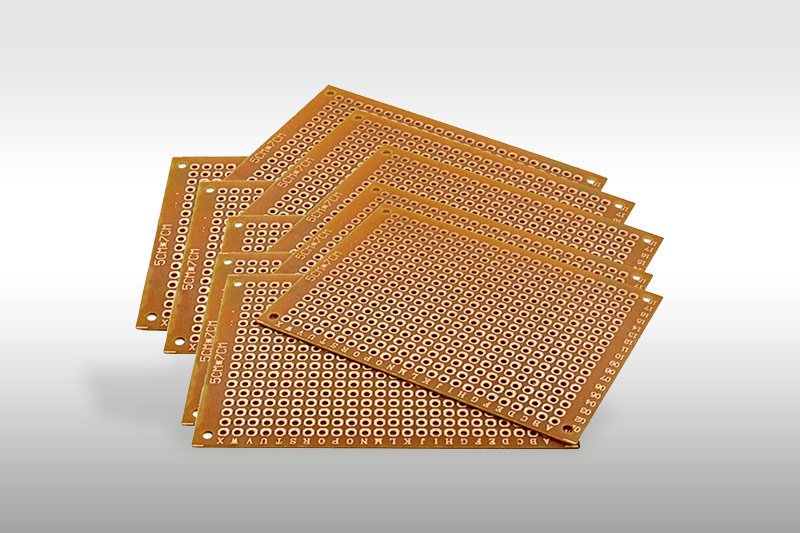

It is the industry standard for:

► PCB substrates

► Motor insulation parts

► General electrical applications

FR4 = Flame-retardant G10

2. High-Temperature Grades: G11 & FR5

When applications require higher thermal stability, G11 and FR5 become the better options.

G11 – High-Temperature Epoxy Glass Laminate

G11 – High-Temperature Epoxy Glass Laminate

G11 uses a modified high-temperature epoxy resin, offering:

► Higher glass transition temperature (TG)

► Improved heat resistance

► Better mechanical strength retention in hot environments

FR5 – Flame-Retardant G11

FR5 – Flame-Retardant G11

FR5 combines the advantages of G11 with UL94-V0 flame retardancy, making it ideal for:

► Harsh industrial environments

► High heat + mandatory flame-retardant requirements

► High-voltage insulation parts

FR5 = Flame-retardant G11

3. Temperature Performance Comparison

Below is the simplified thermal performance gap between the four grades:

Long-Term Temperature Resistance

• G11 & FR5 outperform G10/FR4 by 30–60°C

• They maintain mechanical/electrical stability under continuous heat exposure

Short-Term Peak Temperature

• High-temperature grades handle 50–70°C higher peak temperatures

• Ideal for sudden thermal shock, high-frequency heating, or overload events

4. How to Choose the Right Grade?

Choosing the correct insulation laminate depends on your working temperature, environment, and flame-retardant requirements.

Recommended Selection Guide

|

Working Condition |

Recommended Material |

|

Below 120°C (normal application) |

G10 or FR4 |

|

120–150°C continuous heat |

G11 or FR5 |

|

High-temperature + flame-retardant |

FR5 |

|

General PCB applications |

FR4 |

|

High mechanical + thermal requirements |

G11 |

Using the correct grade not only extends equipment lifespan but also improves operational safety and reduces maintenance costs.

5. Why Temperature Rating Matters in Industrial Insulation

Temperature stability directly affects:

• Insulation aging speed

• Mechanical strength retention

• Electrical reliability under load

• Safety margins for high-voltage equipment

In sectors like EV motors, power transformers, rail transit, and industrial automation, choosing the correct laminate grade is essential for preventing breakdowns and ensuring long-term performance.

Conclusion

G10 and FR4 are suitable for standard-temperature applications, with FR4 offering better flame-retardant performance.

G11 and FR5, on the other hand, are built for harsher, hotter environments, offering significantly better thermal reliability—especially when flame retardancy is required.

By understanding these temperature differences, engineers and buyers can make smarter, safer, and more cost-effective material choices.

If you need G10, FR4, G11, or FR5 sheets, tubes, or custom CNC machined parts, XuJue can provide stable quality, fast delivery, and professional engineering support.