Introduction

American-style box transformer is a widely used product in power distribution system. Unlike European-style box transformer, it is not a simple combination of transformer and high and low switch cabinet, but a comprehensive electrical equipment developed on the basis of transformer. Its characteristic is that the structure of high-voltage side load switch and ring network switch is comprehensively simplified and immersed in the same oil tank with transformer, so the volume is greatly reduced and the cost is correspondingly reduced; another characteristic is that it adopts double fuse protection, and the fuse has dual current and temperature sensitivity, which greatly improves the protection sensitivity and reliability. The fully enclosed and fully insulated performance of American-style box transformer makes installation quick and simple, and can avoid the pain of long-term maintenance. Therefore, since the 1980s, American-style box transformer has been widely used in European and American power distribution systems, especially in the United States, where this type of box transformer has accounted for 80% -90% of distribution transformers. In the early 1990s, American-style box transformer began to be introduced into China. After years of development, there are currently more than tens of thousands of box transformers serving the domestic power distribution system, which are widely used in industrial parks, residential areas, commercial centers and high-rise buildings.

Features of American box transformer

► Compact structure and small size, about 1/3 of the European box transformer with the same capacity and 1/5 of the distribution room.

►Fully enclosed, fully insulated structure, no insulation distance required, reliable guarantee of personal safety; load current can be cut off to achieve full range current protection.

►There are two power supply modes, ring network and terminal, to choose from, with the basic functions of substation.

►Double fuse protection is adopted to effectively reduce the operating cost.

►Easy to install, simple to maintain, and relatively low comprehensive cost.

►High protection level and excellent weather resistance.

►Strong overload capacity, allowing overload of 2 times for 2 hours and 1.6 times for 7 hours without affecting the service life.

►Energy saving and environmental protection, loss is lower than the national standard; stable operation; the cable head has the function of isolating switch, easy and flexible operation.

►Adopting Dyn 11 connection method and three-phase five-column structure, high voltage quality, no drift of neutral point, no heat generation of the box, low noise, good lightning protection performance.

►The surface of the box adopts anti-corrosion design and special spray painting treatment, which can be widely used in various harsh environments, such as stormy snow, highly polluted areas, etc..

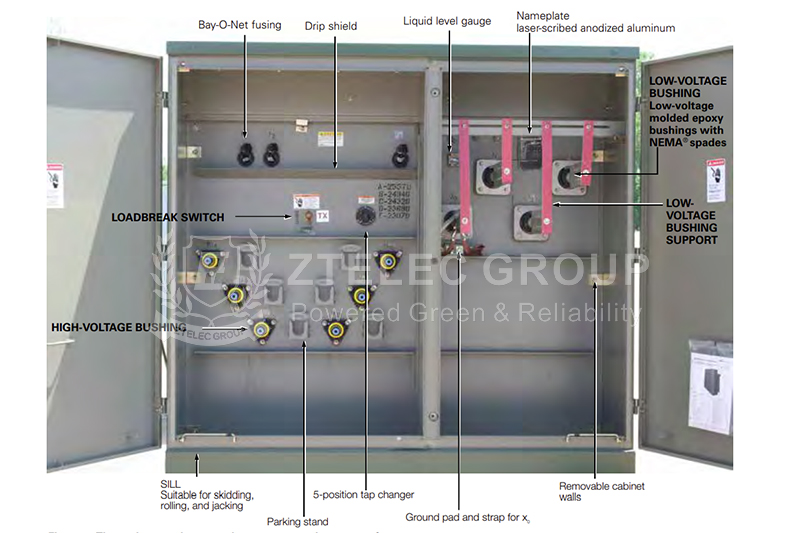

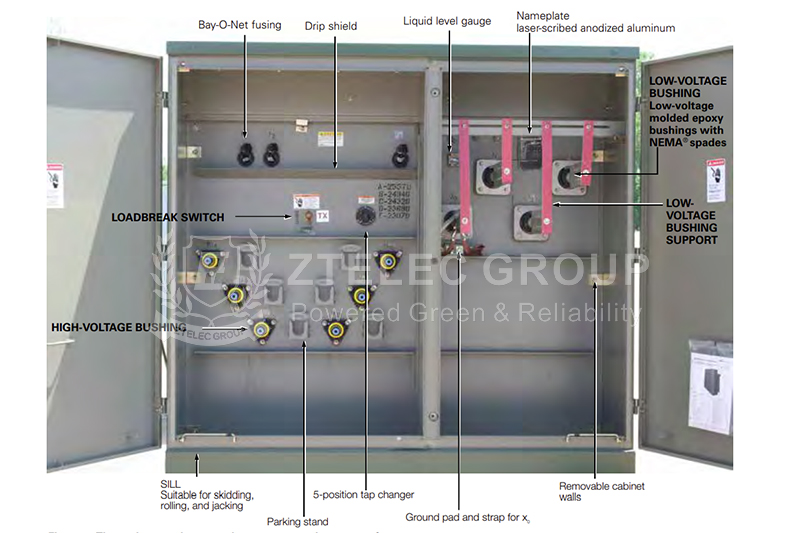

Structure

The structure of the American box transformer is divided into two parts: the front and the rear. The front part is the high and low voltage operation compartment, which includes high and low voltage terminals, load switch, no-load voltage tap changer, plug-in fuse, pressure relief valve, oil thermometer, oil level gauge, oil filling hole, and oil drain valve. The rear part is the oil filling box and heat sink. The transformer winding and core, high-voltage load switch and protective fuse are all in the oil filling box. The box is a fully sealed structure, and concealed high-strength bolts and oil-resistant nitrile rubber gaskets are used to seal the box cover. The box design fully considers the requirements of waterproofing, safety and easy operation. The box door is a three-point interlock, and the high-voltage compartment can only be opened after the low-voltage compartment is opened.

Oil immersed transformer

The Oil immersed transformer design is fundamentally consistent with conventional Oil immersed transformer design principles. The core material can be high-permeability silicon steel or amorphous alloy, and the core structure can be laminated or wound. The windings can be made of copper wire or copper foil.

High-Voltage System and Output Methods

The high-voltage system wiring methods include ring network type, terminal type, and terminal dual-circuit type. The ring network type features “one input, two outputs”: one power input, one output from the transformer’s low-voltage side, and another leading to another transformer or electrical device, providing power to the low-voltage side of another transformer or other equipment. The terminal type features “one input, one output”: one power input and one output from the transformer’s low-voltage side. The terminal dual-circuit type features “one input, one output, one backup”: one power input, one output from the transformer’s low-voltage side, and one backup power supply, which provides power in case of a main power supply failure.

Elbow Bushing (Elbow Cable Plug)

The high-voltage input of the combination transformer is achieved through underground cables using elbow-type cable heads, which consist of three parts: the elbow connector, load socket, and bushing sleeve. The elbow connector comes in single-pass and double-pass types. The single-pass type connects directly to the cable and the high-voltage grid, while the double-pass type connects one end to a lightning arrester and the other to a voltage source.

Lightning Arrester

The lightning arrester primarily serves as protection against lightning strikes and comes in internal and external types. The internal type is placed inside the oil tank at the high-voltage output for protection.

Other Components

No-load switches, oil level gauges, pressure gauges, temperature gauges, pressure relief valves, and other components. Additional components such as low-voltage air circuit breakers, secondary-side metering, and compensation devices can be installed as needed. The transformer’s fuses, multi-position ring network load switches, and no-load tap changers are installed as components inside the oil tank, allowing easy replacement of fuses or operation of load switches to change the transformer’s operating conditions. The high-voltage side is powered by load-break elbow-type cables, and the low-voltage output compartment is installed outside the tank, with space for additional protective devices and instruments as required. All live parts are enclosed within the oil tank, with no exposed live components.

Protection System

The American-style pad-mounted transformer protection system uses high-voltage current-limiting fuses and overload protection fuses in series for high-voltage protection, and low-voltage air circuit breakers for overload and short-circuit protection in the low-voltage circuit. The plug-in fuse (overload protection fuse) has excellent tolerance to transformer surges and is primarily used to protect the transformer during overloads and low-voltage short circuits. The backup protection fuse (high-voltage current-limiting fuse) can safely interrupt all expected currents that could cause melting and is mainly used to protect the transformer and distribution system during internal faults.

Application

Shipping