Bakelite Sheet Applications in Power Distribution Panels: Reliable Insulation for Switchgear Systems

In modern electrical systems, switchgear and power distribution control panels play a crucial role in ensuring safe, stable, and efficient power management. Within these systems, the Bakelite sheet has become an indispensable insulating and structural material due to its excellent electrical, thermal, and mechanical performance. This article explores the key advantages and applications of Bakelite sheets in distribution control panels, helping engineers and buyers better understand why this material remains a trusted choice for industrial power systems.

1. Why Bakelite Sheet Is Essential in Power Distribution Panels

A distribution control panel typically includes components such as circuit breakers, contactors, relays, and control switches. These elements operate under high voltage and current conditions, making insulation and mechanical protection critical.

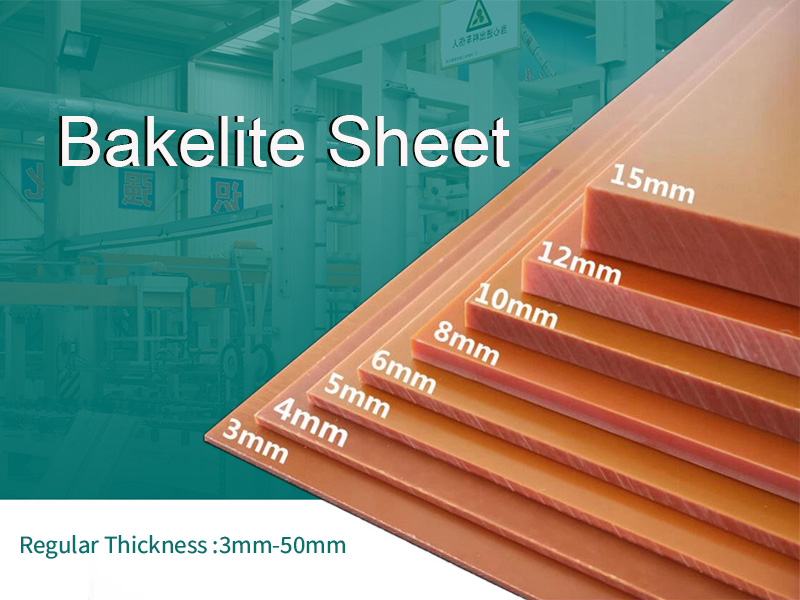

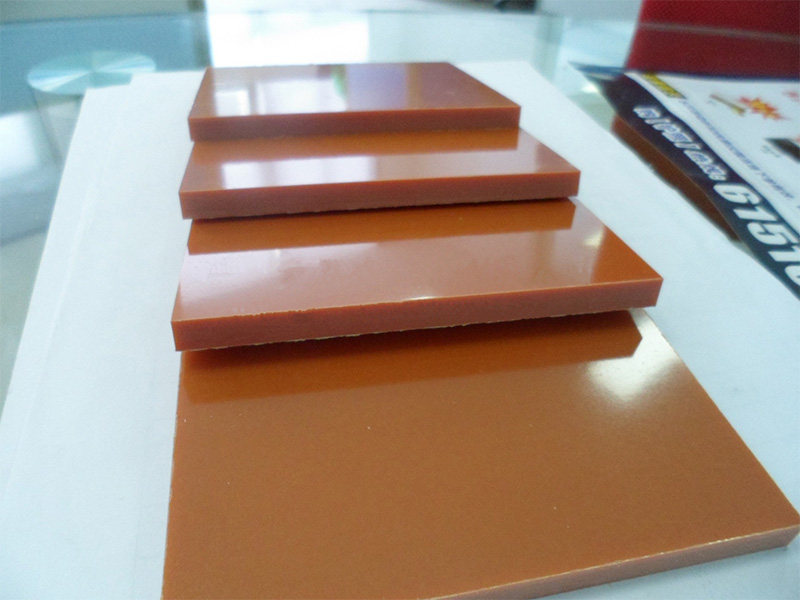

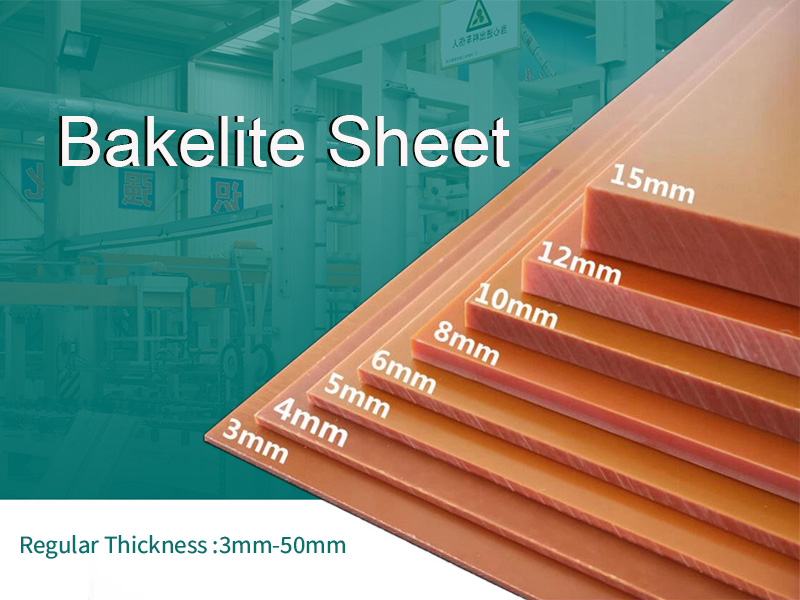

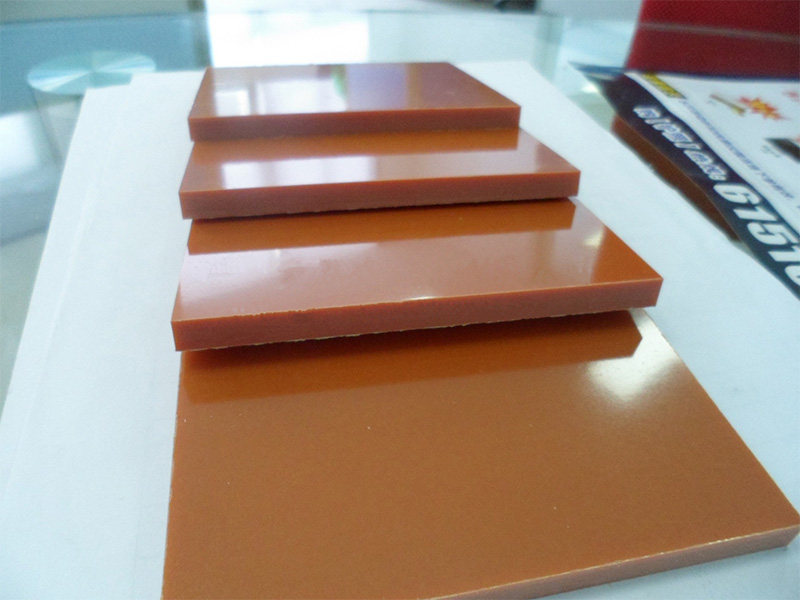

The Bakelite sheet—a thermosetting phenolic resin laminate reinforced with paper or fabric—offers several unique properties that make it ideal for this demanding environment:

• Excellent dielectric strength: Bakelite sheets can withstand high voltage without breakdown, ensuring safe operation of switchgear and control circuits.

• Good thermal resistance: With a working temperature range typically between 120°C and 160°C, Bakelite can resist heat generated by continuous load operation.

• High mechanical strength: Even under mechanical stress from mounting screws or vibration, Bakelite maintains structural stability and dimensional accuracy.

• Flame retardancy and arc resistance: It resists tracking and surface discharge, which are common in high-voltage systems.

These properties make bakelite sheet for electrical insulation a preferred material for fabricating control panel partitions, terminal boards, and insulating mounting plates.

2. Common Applications in Switchgear and Control Systems

In low- and medium-voltage switchgear, Bakelite sheets serve both insulating and structural functions. Key applications include:

• Base plates and mounting boards: Used to fix electrical components while ensuring isolation between live and grounded parts.

• Busbar supports and spacers: Bakelite’s mechanical rigidity allows it to hold copper busbars in position without deformation or electrical leakage.

• Insulating barriers and arc shields: In high-voltage cabinets, Bakelite prevents flashover between phases and enhances personnel safety.

• Panel faceplates and enclosures: Its smooth, machinable surface allows for precise drilling and cutting, enabling neat, professional panel layouts.

In addition, custom-machined Bakelite parts are widely used in transformer terminal covers, motor starters, and control relays, where compact design and insulation reliability are essential.

3. Comparing Bakelite Sheet with Other Insulation Materials

When selecting materials for switchgear manufacturing, engineers often compare Bakelite with FR4 epoxy sheet and G10 fiberglass laminate. While FR4 and G10 provide higher mechanical and moisture resistance, Bakelite sheet offers a cost-effective balance of performance, machinability, and insulation capability.

For low- and medium-voltage systems (below 35kV), Bakelite is sufficient for most applications, especially when cost control and easy processing are priorities.

4. Quality and Compliance in Bakelite Sheet Production

High-quality Bakelite sheets for electrical applications comply with standards such as IEC 60893 and GB/T 1303.1, ensuring consistent dielectric strength, mechanical endurance, and dimensional tolerance.

At XuJue, each Bakelite sheet undergoes strict inspection for thickness accuracy, insulation resistance, and heat tolerance before delivery. Custom thicknesses and precision-cut panels are available to fit different switchgear designs.

5. Conclusion

The use of Bakelite sheet in power distribution panels represents a proven engineering solution for reliable electrical insulation, mechanical stability, and cost efficiency. Its continued adoption across industrial switchgear, control cabinets, and power distribution systems demonstrates its versatility and dependability.

For electrical equipment manufacturers seeking durable and affordable insulation solutions, phenolic Bakelite sheets remain a top-performing material — one that perfectly balances safety, performance, and practicality in modern switchgear systems.